Influence of Some Additives On The Efficiency of Viscosity Index Improver For Base Lubricating Oils

Uploaded by

mgamal1080Influence of Some Additives On The Efficiency of Viscosity Index Improver For Base Lubricating Oils

Uploaded by

mgamal1080Number 1 Volume 20 January 2014 Journal of Engineering

Influence of Some Additives on the Efficiency of Viscosity Index

Improver for Base Lubricating Oils

Prof. Dr. Talib Bahjat Kashmoula

Tiba Naif Jasim

E-mail: [email protected]

Chemical Engineering Department, Collage of Engineering, Alnahrain University, Baghdad, Iraq

ABSTRACT

The effects of three different additives formulations namely Lubrizol 21001, HiTEC 8722B and

HiTEC 340 on the efficiency of VII namely OCP of three base lubricating oils namely 40 stock and 60

stock and 150 stock at four temperatures 40, 60, 80 and 100oC were investigated. The efficiency of OCP

is decreased when blended with 4 and 8 wt% of Lubrizol 21001 for all the three base oil types. But it is

increased when adding 4 wt% and 8 wt% of H-8722B in 40 stock. While for 60 stock and 150 stock the

OCP efficiency decreased by adding 4 and 8 wt% of H-8722B. In the other hand, it is decreased with a

high percentage by adding 4 and 8 wt% of H-340 for 60 stock and 150 stock and for 40 stock it is

increased by adding 4 wt% of H-340 and decreased with insignificant percentage when adding 8 wt%.

Finally, a number of VI correlations have been obtained depending on the results predicted in this study.

These correlations represent the functional relationships between the VI and the concentration of OCP for

three types of base lubricating oil and for each type of additives.

Keywords: Lubricating oil, Kinematic Viscosity, Viscosity Index, Viscosity Index Improver,

Additives, Temperatures.

ﺗﺄﺛﻴﺮ ﺑﻌﺾ ﺍﻟﻤﻀﺎﻓﺎﺕ ﻋﻠﻰ ﻛﻔﺎءﺓ ﻣﺆﺷﺮ ﻣﺤﺴﻦ ﺍﻟﻠﺰﻭﺟﺔ ﻟﺰﻳﻮﺕ ﺍﻟﺘﺰﻳﻴﺖ ﺍﻷﺳﺎﺱ

ﻁﺎﻟﺐ ﺑﻬﺠﺖ ﻛﺸﻤﻮﻟﺔ.ﺩ.ﺃ

ﻁﻴﺒﺔ ﻧﺎﻳﻒ ﺟﺎﺳﻢ

ﺍﻟﻌﺮﺍﻕ، ﺑﻐﺪﺍﺩ، ﺟﺎﻣﻌﺔ ﺍﻟﻨﻬﺮﻳﻦ، ﻛﻠﻴﺔ ﺍﻟﻬﻨﺪﺳﺔ،ﻗﺴﻢ ﺍﻟﻬﻨﺪﺳﺔ ﺍﻟﻜﻴﻤﻴﺎﻭﻳﺔ

ﺍﻟﺨﻼﺻﺔ

Lubrizol 21001 ﻓﻲ ﻫﺬﺍ ﺍﻟﺒﺤﺚ ﺗﻤﺖ ﺩﺭﺍﺳﺔ ﺗﺄﺛﻴﺮ ﺛﻼﺛﺔ ﺃﻧﻮﺍﻉ ﻣﻦ ﺍﻟﻤﻀﺎﻓﺎﺕ ﺍﻟﻤﺴﺘﺤﺼﻠﺔ ﻣﻦ ﻣﺼﻔﻰ ﺍﻟﺪﻭﺭﺓ ﻓﻲ ﺑﻐﺪﺍﺩ ﻭﺍﻟﺘﻲ ﻫﻲ

ﻭﺍﻟﺬﻱ ﻳﺴﺘﺨﺪﻡ ﻟﺰﻳﻮﺕ ﺍﻟﺘﺰﻳﻴﺖOlefin Copolymer ﻋﻠﻰ ﻛﻔﺎءﺓ ﻣﺤﺴﻦ ﻣﺆﺷﺮ ﺍﻟﻠﺰﻭﺟﺔ ﻣﻦ ﻧﻮﻉHiTEC 340 ﻭHiTEC 8722B ﻭ

ﻭﺗﻤﺖ ﺍﻟﺪﺭﺍﺳﺔ ﻋﻨﺪ ﺃﺭﺑﻊ. 150 stock ﻭ60 stock ﻭ40 stock ﺍﻷﺳﺎﺱ ﺍﻟﺜﻼﺛﺔ ﺍﻟﻤﺴﺘﺤﺼﻠﺔ ﺃﻳﻀﺎ ﻣﻦ ﻣﺼﻔﻰ ﺍﻟﺪﻭﺭﺓ ﻭﺍﻟﺘﻲ ﻫﻲ

%wt 8 ﻭ4 ( ﺗﻘﻞ ﺑﻤﻌﺪﻝ ﺗﺼﺎﻋﺪﻱ ﻋﻨﺪ ﺧﻠﻂOCP) ﻭﺟﺪ ﺇﻥ ﻛﻔﺎءﺓ ﻣﺤﺴﻦ ﻣﺆﺷﺮ ﺍﻟﻠﺰﻭﺟﺔ.ﻡo 100 ﻭ80 ﻭ60 ﻭ40 ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﻫﻲ

ﻣﻦ ﺍﻟﻤﻀﺎﻑ%wt 8 ﻭ%wt 4 ﻭﻟﻜﻦ ﻫﺬﻩ ﺍﻟﻜﻔﺎءﺓ ﺗﺘﺤﺴﻦ ﺑﺈﺿﺎﻓﺔ. ﻷﻧﻮﺍﻉ ﺯﻳﻮﺕ ﺍﻟﺘﺰﻳﻴﺖ ﺍﻟﺜﻼﺙLubrizol 21001 ﻣﻦ ﺍﻟﻤﻀﺎﻑ

8 ﻭ4 ﺗﻘﻞ ﻋﻨﺪ ﻛﻼ ﺍﻟﺘﺮﻛﻴﺰﻳﻦOCP ﻓﺈﻥ ﻛﻔﺎءﺓ150 stock ﻭ60 ﺑﻴﻨﻤﺎ ﻟﻠﻨﻮﻋﻴﻦ.40 stock ﻋﻨﺪ ﺧﻠﻄﻪ ﻣﻊ ﺍﻟﺰﻳﺖHiTEC 8722B

ﻓﺈﻥ ﻛﻔﺎءﺓ ﻣﺤﺴﻦ ﻣﺆﺷﺮ ﺍﻟﻠﺰﻭﺟﺔ ﺗﻨﺨﻔﺾ ﺑﻤﻘﺪﺍﺭ ﻛﺒﻴﺮ%wt 8 ﻭ4 ﻭﺑﻜﻼ ﺍﻟﺘﺮﻛﻴﺰﻳﻦHiTEC 340 ﻟﻮﺣﻆ ﺇﻧﻪ ﻋﻨﺪ ﺧﻠﻂ ﺍﻟﻤﻀﺎﻑ.%wt

8 ﻓﺈﻥ ﺍﻟﻜﻔﺎءﺓ ﺗﺰﺩﺍﺩ ﺑﻴﻨﻤﺎ ﺗﻘﻞ ﻋﻨﺪ ﺧﻠﻄﻪ ﺑﺘﺮﻛﻴﺰ%wt 4 ﻭﺑﺘﺮﻛﻴﺰ40 stock ﺑﻴﻨﻤﺎ ﻋﻨﺪ ﺧﻠﻄﻪ ﻣﻊ ﺍﻟﺰﻳﺖ.150 stock ﻭ60 ﻟﻠﻨﻮﻋﻴﻦ

ﺃﻳﻀﺎ ﺗﻢ ﺇﻳﺠﺎﺩ ﻋﺪﺓ ﻣﻌﺎﺩﻻﺕ ﺗﺮﺑﻂ ﺑﻴﻦ ﻣﺆﺷﺮ ﺍﻟﻠﺰﻭﺟﺔ ﻭﺗﺮﻛﻴﺰ ﻣﺤﺴﻦ ﻣﺆﺷﺮ ﺍﻟﻠﺰﻭﺟﺔ ﻟﻜﻞ ﻧﻮﻉ ﻣﻦ ﺯﻳﻮﺕ ﺍﻟﺘﺰﻳﻴﺖ ﺍﻟﺜﻼﺙ ﻭﻟﻜﻞ.%wt

.ﻧﻮﻉ ﻣﻦ ﺍﻟﻤﻀﺎﻓﺎﺕ ﺍﻟﺜﻼﺛﺔ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ

. ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ، ﻣﻀﺎﻓﺎﺕ، ﻣﺤﺴﻦ ﻣﺆﺷﺮ ﺍﻟﻠﺰﻭﺟﺔ، ﻣﺆﺷﺮ ﺍﻟﻠﺰﻭﺟﺔ، ﺍﻟﻠﺰﻭﺟﺔ ﺍﻟﻜﻴﻨﻤﺎﺗﻴﻜﻴﺔ، ﺯﻳﻮﺕ ﺍﻟﺘﺰﻳﻴﺖ:ﻛﻠﻤﺎﺕ ﺭﺋﻴﺴﻴﺔ

31

Talib Bahjat Kashmoula Influence of Some Additives on the Efficiency of Viscosity

Tiba Naif Jasim Index Improver for Base Lubricating Oils

1. INTRODUCTION:

o

Lubricant may serve many purposes such as API gravity of 23.90 (measured in the Research

conducting the heat of friction away from the and Quality Control Laboratory, 2012).

bearings, serving as a seal to exclude undesirable Olefin Copolymer (OCP) of type PVC-100

substances from the area being lubricated, acting XA is a VII (solute) for base lubricating oil

as a carrier for rust preventive, anti-friction (solvent). OCP is a polymer composed of two or

agents, extreme pressure additives and other more different monomer. The OCPs have

properties. However, their primary purpose is in unknown structure, different companies are

general to lubricate, i.e., to reduce friction producing them.

(Zuidema, 1959). Lubricating oil additives are This type of VII is designed to provide a

normally used in low concentrations from a careful balance of thickening power, low-

fraction of a one percent to five percent or may be temperature fluidity, shear stability and high-

more. Their purposes may be to impart extreme temperature viscosity (McCrum, 1997).

pressure characteristics, reduce pour point, Three types of additives (Lubrizol 21001,

improve the viscosity index, reduce bearing HiTEC 8722B and HiTEC 340) were obtained

corrosion, reduce or eliminate foaming and so on from Al-Daura Refinery. Lubrizol 21001 is a

(Hobson, 1984). The selection of right additive or multipurpose additive for otto engine. The

of the most suitable combination of additives recommended dosage is 10.8% by weight. This

depends on the specific use of the oil (Brouwer, additive when formulated with the appropriate

1966). base stocks and VII will meet the requirements of

The most important property of lubricating oil ACEA A3/B4-04(2004), API SL, API CF, and

is its kinematic viscosity, which is a measure of Volkswagen VW50101 (2005) (Research and

its internal friction or ability to flow and largely Quality Control Laboratory, 2012).

determines its suitability for any particular HiTEC 8722B is a multipurpose additive for

application (Brouwer, 1966). diesel engine. It provides efficient additive

The kinematic viscosity of an oil decreases solutions according to API, ACEA and OEMs

with rising in temperature but to varying degree heavy-duty diesel requirements. This additive has

depending on the type of crude oil from which it been designed to offer cost optimized

is derived and the refining treatment to which it formulations and delivers a number of customer

has been subjected. The relationship between benefits. Its package approval is supported by

viscosity and temperature is the significance for complete engine test data. The recommended

lubricating oils since most oils have to operate dosage is 7.8% by weight. And it allows the use

over a range of temperatures. There are many of a wide range of base oils and VIIs (Afton

ways of expressing this relationship but the one Company, HiTEC-8722B).

firmly established in the petroleum industry is HiTEC 340 is an economic automotive gear

viscosity index (VI) system, even though it is an oil additive. It is used for axles and transmissions.

arbitrary system and more fundamental methods It provides robust performance in automotive

have been suggested (Bill Hires, 1993). applications, cost savings at all treat-rates,

extensive history of trouble-free performance and

2. MATERIALS: suitable for unharmed drain. The recommended

In this study, the experimental work will be dosage is 4% by weight and its treat-rates may

carried out on Iraqi paraffinic oils which have vary depending on base oil type (Afton Company,

three types of base-stocks that were obtained from HiTEC-340).

Al-Daura Refinery, namely 40, 60 and 150 stock.

These types of base stocks were processed as base 3. EXPERIMENTAL WORK:

lubricating oil without additives. The lightest one The composition of each mixture was prepared as

is 40 stock with oAPI gravity of 34.976, the weight percentage for more accuracy than mole

middle type is 60 stock which have oAPI gravity percentage. Mixing process was made by stirring

of 29.24 and 150 stock is the heaviest type with and heating to about 50-60oC at the same time to

ensure thorough mixing.

32

Number 1 Volume 20 January 2014 Journal of Engineering

Viscosity measurements were taken 3. 150 stock with 4 and 8 wt% of H-340 with 2-8

immediately, after preparing the mixture to avoid wt% of OCP.

deposit formation or vaporizing the light ends. All Cannon Fenske Routine Viscometers (the

these measurements were taken at the glass capillary type) with different sizes were

atmospheric pressure. used for measuring the time of the solvent (base

The following mixtures were prepared in this oil) (to) and time of mixtures (t) which are used in

study: calculating the kinematic viscosity of transparent

1) Binary Mixtures: Newtonian liquids according to the Standard Test

There were four types of binary mixtures, Method for Kinematic Viscosity of Transparent

as follows: and Opaque Liquids (ASTM D 445–03).

a) Binary mixtures of each type of Times measured are used to calculate the

oil-stock (40, 60 and 150 stock) kinematic viscosity using the following equation:

with 0-10 wt% of OCP.

b) Binary mixtures of each type of (1)

oil-stock (40, 60 and 150 stock)

with 0-10 wt% of Lubrizol Where: ν is the kinematic viscosity (mm2/s), t is

21001. the measured time (s) and f is the viscometer

c) Binary mixtures of each type of factor.

oil-stock (40, 60 and 150 stock) The VI as mentioned before is an arbitrary

with 0-10 wt% of H-8722B. scale for comparing the rates of viscosity changes

d) Binary mixtures of each type of of lubricating oil with temperature. The VI scale

oil-stock (40, 60 and 150 stock) was set up by the SAE. The temperatures chosen

with 0-10 wt% of H-340. arbitrarily for reference are 40 and 100°C.

2) Ternary Mixtures:

These ternary mixtures were prepared as 4. RESULTS AND DISCUSSION:

follows:

a) 40 stock: The effect of temperature on the VI of the

1. 40 stock with 4 and 8 wt% of three types of base lubricating oil was measured.

Lubrizol 21001 with 2-8 Table 1 shows the values of VI which are

wt% of OCP. obtained from the kinematic viscosities and the

2. 40 stock with 4 and 8 SAE VI scale at the two reference temperatures

wt% of H-8722B with 2- 40 and 100°C.

8 wt% of OCP. Blends from the three types of base stocks

3. 40 stock with 4 and 8 with different concentrations of OCP with a range

wt% of H-340 with 2-8 of 0-10 wt% were prepared. Those blends give a

wt% of OCP. significance increase in the kinematic viscosity

b) 60 stock: and VI as the weight percent of OCP increase.

1. 60 stock with 4 and 8 This is because OCP composed of long and

wt% of Lubrizol 21001 flexible polymer molecules that interact with the

with 2-8 wt% of OCP. base stocks and this interaction leads to increase

2. 60 stock with 4 and 8 the resistance to flow (Canter, 2011).

wt% of H-8722B with 2- The concentration of OCP must be limited,

8 wt% of OCP. because the additional effects may then arise from

3. 60 stock with 4 and 8 intermolecular forces and entanglements between

wt% of H-340 with 2-8 chains. Therefore, OCP is excellent in economical

wt% of OCP. efficiency, because it exhibits the effect even if it

c) 150 stock: is added in a small amount (Kaneshige, 2009).

1. 150 stock with 4 and 8 It is noticed that the increase in OCP

wt% of Lubrizol 21001 concentration, which blended with the base oils,

with 2-8 wt% of OCP. will improve the VI as shown in Figure 1. It

2. 150 stock with 4 and 8 wt% of H-8722B with 2- affects 40 stock by 154%, 60 stock by 90% and

8 wt% of OCP. 150 stock by 57%, by adding 10 wt% of OCP.

33

Talib Bahjat Kashmoula Influence of Some Additives on the Efficiency of Viscosity

Tiba Naif Jasim Index Improver for Base Lubricating Oils

Also, the improving in VI will be with a that at a specific concentration of Lubrizol 21001,

decreasing rate as the concentration of OCP when blended with the three types of base oil, the

increased. VI will be improved with the increasing of OCP

In the other hand, the three types of additives concentration.

(Lubrizol 21001, HiTEC 8722B, and HiTEC 340) Also it can be noticed that at all OCP

will blend with the three types of base oil in a concentrations the VI will be decreased as the

concentration range of 0-10 wt% and temperature concentration of Lubrizol 21001 increased.

range of 40-100oC. And their effects on the The efficiency of OCP is performed by

kinematic viscosity and VI were different as measuring the VI of blends before and after

shown in Figures 2, 3 and 4. adding Lubrizol 21001. For 40 and 150 stock, the

For Lubrizol 21001, it has been found that decreasing rate of OCP efficiency is calculated to

the enhancement in the VI for 40 stock is more be about 7% and 10% by adding 4 and 8 wt% of

pronounced than for 60 and 150 stock as sketched Lubrizol 21001, respectively. While the

in Figure 2. The increasing in VI is about 35%, decreasing rate of the efficiency is obtained to be

10% and 8% for 40, 60 and 150 stock, about 10% and 16% when 60 stock is blended

respectively when adding 10 wt% of Lubrizol with 4 and 8 wt% of Lubrizol 21001, respectively.

21001. Also it has been noticed that the rate of So it is not preferred to use Lubrizol 21001as

improvement in the VI for 40 stock is in a range lubricating oil additive in the presence of OCP

of 7.5-10%, while it is 2% for 60 stock and 1.1- because it lowers the VI as well as the efficiency

2.2% for 150 stock with every 2 wt% added of of the VII.

Lubrizol 21001. For H-8722B its effect is drawn in Figures 8,

For the second type of additives which is H- 9 and 10. It can be indicated that the VI is

8722B, it has been found that the improving in the improved with increasing OCP concentration at

VI for 40 stock is very noticeable more than for the two concentrations of H-8722B because this

60 and 150 stock as shown in Figure 3. The additive is composed of long and flexible polymer

increasing in VI is about 22%, 5% and 2% for 40, molecules that interact with the base oil and OCP.

60 and 150 stock, respectively when adding 10 This interaction will cause greater volume and the

wt% of H-8722B. So it recommended using such base oil produces a proportionally greater

additive with light oil types like 40 stock because thickening effect which in turn raises the VI of

of its insignificance effect on both 60 and 150 the oil (Shawn, 2002). In the other hand at all

stock. OCP concentrations the VI will be decreased as

While for the third type of additives which is the concentration of H-8722B increased.

H-340, it can be seen from Figure 4 that the With respect to the efficiency of OCP, the 60

maximum VI is obtained at different stock showed the same behavior as in adding

concentrations of H-340. These concentrations are Lubrizol 21001 by having the highest decreasing

2 wt% for 40 stock and 150 stock whereas 2, 4 rate for the OCP efficiency which was about 7%

and 6 wt% for 60 stock. and 14% by adding 4 and 8 wt% of H-8722B,

These concentrations are very helpful in respectively. While for 150 stock the decreasing

selecting the base oil type and the recommended rate is obtained to be about 2% by adding 4 wt%

dosage of H-340 for producing effective and and being 4% by adding 8 wt% of H-8722B.

economic automotive gear oil. Such behavior of It is interesting to know that for 40 stock the

additive on the VI was also obtained by using the efficiency is increased by 5% when adding 4 wt%

PIB and PBR with the base oil types (Tanveer, and it increased by insignificant value when

2006). adding 8 wt% of H-8722B so it is better to use H-

But in order to study the influence of the three 8722B as lubricating oil additive in the presence

additives on the efficiency of OCP, two sets of of OCP by adding 4 wt% or less.

mixtures from a base stock, OCP and an additive Finally, the VI Figures from 11, 12 and 13

were prepared with an additive concentration of 4 showed the effect of H-340 on the three base oil

wt% in the first set and 8 wt% in the second with types and OCP.

the three types of base stocks (40, 60 and 150 It can be noticed that the VI is improved with

stock) and OCP concentration range of 2-8 wt%. increasing OCP concentration at the two

The effect of Lubrizol 21001 on the VI is concentrations of H-340. And at all OCP

sketched in Figures 5, 6 and 7. It can be shown

34

Number 1 Volume 20 January 2014 Journal of Engineering

concentrations the VI will be decreased as the For 40 stock:

concentration of H-340 increased.

As for the efficiency of OCP, this additive

would strongly decrease the OCP efficiency of (5)

the 60 stock, the decreasing rate for the OCP

which was about 37% and 28% by adding 4 and 8

wt% of H-340, respectively. While for 150 stock For 60 stock:

the decreasing rate is obtained to be about 10% by

adding 4 wt% and being about 14% by adding 8 (6)

wt% of H-340.

It is a coincidence that for 40 stock the

For 150 stock:

efficiency at 4 wt% of H-340 is increased just like

in H-8722B which it was by about 5% and it also

(7)

decreased when adding 8 wt% of H-340. So it is

better to use H-340 as lubricating oil additive in

the presence of OCP by adding 4 wt% or less. b. At 8 wt% of Lubrizol 21001:

For 40 stock:

5. CORRELATIONS FOR VI

(8)

A number of VI correlations have been

obtained in this section using the regression For 60 stock:

analysis and depending on the results which

presented in the previous section of this study. (9)

The functional relationships are between the

VI and the concentration of OCP for three types For 150 stock:

of base lubricating oil and for each type of

additives. (10)

From Table 2 three correlations between VI

and the OCP concentration where obtained as

Also for H-8722B the functional relationships

shown below:

were obtained using the regression analysis

depending on Tables 5 and 6. The correlations are

For 40 stock:

given bellow:

a. At 4 wt% of H-8722B:

For 40 stock:

(2)

For 60 stock:

(11)

(3)

For 60 stock:

For 150 stock: (12)

(4)

For 150 stock:

For Lubrizol 21001 it has been noticed that (13)

the correlations at 4 wt% of this additive is

different from the correlations of 8 wt%. From

b. At 8 wt% of H-8722B:

Tables 3 and 4 the functional relationships were

For 40 stock:

obtained as follows:

(14)

a. At 4 wt% of Lubrizol 21001:

35

Talib Bahjat Kashmoula Influence of Some Additives on the Efficiency of Viscosity

Tiba Naif Jasim Index Improver for Base Lubricating Oils

1. The kinematic viscosity and viscosity index of the

For 60 stock: light oil (40 stock) is affected more than the

medium oil (60 stock) and the heavy oil (150

(15) stock) and this can be attributed to the fact that

the rate of change with temperature depends

For 150 stock: largely on the type of base oil.

2. The kinematic viscosity of the mixtures prepared

(16) from base oil, viscosity index improver and

additives will decrease with increasing

temperature as their resistance to flow will

For H-340 the correlations at 4 wt% of this

decrease.

additive is different from the correlations of 8

3. The used additives (Lubrizol 21001, H-8722B

wt%. These functional relationships were

and H-340) are packages contain a polymeric

obtained depending on Tables 7 and 8 as follows:

chain behaves as a viscosity index improver. So

a. At 4 wt% of H-340:

when those additives are blended with only the

For 40 stock:

base oil the viscosity index will increase slightly

and this is recommended in monograde oils.

(17)

While when those additives are blended with the

base oil and with a viscosity index improver like

For 60 stock: OCP, the obtained oil will be a multigrade oil.

4. The viscosity index for both 40 and 150 stock

(18) when blended with 2 wt% of H-340 additive will

increase by about 4% and at higher concentrations

For 150 stock: it will decrease. While for 60 stock at 2, 4 and 6

wt% of H-340 the viscosity index will increase

(19) negligibly and then decrease at higher

concentrations.

b. At 8 wt% of H-340: 5. The efficiency of OCP (VII) is decreased with an

For 40 stock: increasing rate when blended with 4 and 8 wt% of

Lubrizol 21001 for all the three base oil types.

(20) 6. The efficiency of OCP is increased by 5% when

adding 4 wt% of H-8722B in 40 stock and

increase by insignificant value when adding 8

For 60 stock:

wt%. For 60 stock the OCP efficiency decreased

by a rate of about 7% and 14% by adding 4 and 8

(21)

wt% of H-8722B, respectively. While for 150

stock the efficiency of OCP decreased the

For 150 stock: decreasing rate is obtained to be about 2% by

adding 4 wt% and being 4% by adding 8 wt% of

(22) H-8722B. So it is better to use this additive with

lubricating oil in the presence of OCP by adding 4

For the correlations above the error wt% or less.

percentage is in the range of 2-3%. These 7. H-340 would strongly decrease the efficiency of

functional relationships are applicable only for OCP for 60 stock, the decreasing rate was about

this set of blends and it can be applied usefully for 37% and 28% by adding 4 and 8 wt% of H-340,

determining the VI values at any OCP respectively. For 150 stock the decreasing rate is

concentration or vise versa. obtained to be about 10% by adding 4 wt% and

being about 14% by adding 8 wt% of H-340.

6. CONCLUSIONS: While for 40 stock the efficiency at 4 wt% of H-

From the proposed study, the following 340 is increased by about 5% and decreased

conclusions have been extracted: insignificantly when adding 8 wt% of H-340. It is

recommended to use H-340 as lubricating oil

36

Number 1 Volume 20 January 2014 Journal of Engineering

additive in the presence of OCP by adding 4 wt% Tanveer, Sabiha and Ram Prasad, Indian Journal

or less. of Chemical Technology, Vol.13, pp. 398-403,

8. Many correlations were obtained for the July, 2006.

VI with respect to the concentration of

OCP. And it has been found that there is Zuidema, H.H., "The Performance of Lubricating

no unified correlation can represent this Oils", 2nd Edition, 1959.

system as whole.

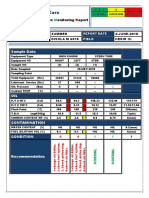

8. Tables and Figures:

7. REFERENCES:

Table 1 VI of Base Lubricating Oil

An American National Standard, “Standard

Test Method for Kinematic Viscosity of Base Lubricating oil type VI

Transparent and Opaque Liquids”, D445-03, 40 stock 106

Part 71, 1990. 97

60 stock

Bill Hires, "How to Select a Lubricating Oil 150 stock 90

for Farm Engines", October, 1993.

Table 2 VI Values of Base Oil Blended with

Brouwer, L.E.J., "The Petroleum OCP

Handbook", 5th Edition, pp. 116-235, 1966. OCP VI of 40 VI of 60 VI of 150

wt% stock stock stock

Canter N., “Viscosity Index Improvers”, 0 106 97 90

September, 2011. http://www.STLE.ORG

2 178 119 105

HiTEC-8722B_PDS.pdf, 2011. 4 223 143 117

http://www.aftonchemical.com 6 248 162 126

8 262 176 133

HiTEC-340_PDS.pdf, 2011. 10 270 185 138

http://www.aftonchemical.com

Table 3 VI Values of Base Oil and 4 wt% of

Hobson, G.D., "Modern Petroleum

Lubrizol 21001 with Different Concentrations

Technology", 5th Edition, Applied Science

of OCP at Different Temperatures

Publishers Ltd., London, 1984.

OCP VI of 40 VI of 60 VI of 150

Kaneshige R., Matsuda A., Ikeda S., Okada wt% stock stock stock

K. and Kawasaki M., “Viscosity Modifier of 2 176 114 103

Lubricating Oil for Power Transmission 4 218 128 110

system and Lubricating Oil Composition for 6 236 142 116

Power Transmission System”, 22 January

8 245 152 122

2009. http://www.freshpatents.com

McCrum, N.G., C.P. Buckley and C.B. Table 4. VI Values of Base Oil and 8 wt% of

Bucknall, "Principles of Polymer Lubrizol 21001 with Different Concentrations

Engineering", 2nd Ed., New York, 1997. of OCP at Different Temperatures

Shawn D., Tsai H. and Orban j., “Lubricants Base OCP VI of 40 VI of 60 VI of 150

stock and Additive Effects on Diesel Engine wt% stock stock stock

Emissions”, National Renewable Energy 2 174 106 101

Laboratory, 2002. 4 200 113 108

6 216 125 113

8 228 132 117

37

Talib Bahjat Kashmoula Influence of Some Additives on the Efficiency of Viscosity

Tiba Naif Jasim Index Improver for Base Lubricating Oils

Table 5. VI Values of Base Oil and 4 wt% of

H-8722B with Different Concentrations of

OCP at Different Temperatures

OCP VI of 40 VI of 60 VI of 150

wt% stock stock stock

2 141 108 97

4 175 118 102

6 194 132 112

8 219 149 121

Table 6. VI Values of Base Oil and 8 wt% of

H-8722B with Different Concentrations of

OCP at Different Temperatures

OCP VI of 40 VI of 60 VI of 150 Fig. 1 Effect of OCP on VI of the Three Types

wt% stock stock stock of Base Lubricating Oil

2 139 100 95

4 163 114 99

6 181 120 108

8 206 128 116

Table 7. VI Values of Base Oil and 4 wt% of

H-340 with Different Concentrations of OCP

at Different Temperatures

OCP VI of 40 VI of 60 VI of 150

wt% stock stock stock

2 134 99 96

4 161 100 99

6 178 103 103

8 207 107 107

Fig. 2 Effect of Lubrizol 21001 on VI of the

Three Types of Base Lubricating Oil

Table 8. VI Values of Base Oil and 8 wt% of

H-340 with Different Concentrations of OCP

at Different Temperatures

OCP VI of 40 VI of 60 VI of 150

wt% stock stock stock

2 131 98 95

4 147 99 97

6 168 101 100

8 190 104 104

38

Number 1 Volume 20 January 2014 Journal of Engineering

Fig. 3 Effect of H-8722B on VI of the Three Fig. 5 Effect of OCP on VI of 40 stock + 0, 4

Types of Base Lubricating Oil and 8 wt% of Lubrizol 21001

115

40stock

60stock

150stock

Viscosity Index (VI)

100

85

0 2 4 6 8 10

H-340, Wt%

Fig. 4 Effect of H-340 on VI of the Three Types Fig.6 Effect of OCP on VI of 60 stock + 0, 4

of Base Lubricating Oil and 8 wt% of Lubrizol 21001

39

Talib Bahjat Kashmoula Influence of Some Additives on the Efficiency of Viscosity

Tiba Naif Jasim Index Improver for Base Lubricating Oils

Fig. 7 Effect of OCP on VI of 150 stock + 0, 4

Fig. 9 Effect of OCP on VI of 60 stock + 0, 4

and 8 wt% of Lubrizol 21001

and 8 wt% of H-8722B

Fig. 8 Effect of OCP on VI of 40 stock + 0, 4 Fig.10 Effect of OCP on VI of 150 stock + 0, 4

and 8 wt% of H-8722B and 8 wt% of H-8722B

40

Number 1 Volume 20 January 2014 Journal of Engineering

Fig. 11 Effect of OCP on VI of 40 stock + 4 and Fig. 13 Effect of OCP on VI of 150 stock +

8 wt% of H-340

4 and 8 wt% of H-340

Notations and Abbreviations

COCP Concentration of Olefin Copolymer,

g/cm3

ACE European Automobile Manufacturers

A Association

API American Petroleum Institute

OCP Olefin Copolymer

OEM Original Element Manufacturer

Fig. 12. Effect of OCP on VI of 60 stock + 4 PBR Poly Butadiene Rubber

and 8 wt% of H-340

PIB Polyisobutylene

SAE Society of Automotive Engineers

VI Viscosity Index

VII Viscosity Index Improver

41

You might also like

- Nlgi Lubricating Grease Production Survey ReportNo ratings yetNlgi Lubricating Grease Production Survey Report17 pages

- Distillation - How To Specify & Install Cartridge TraysNo ratings yetDistillation - How To Specify & Install Cartridge Trays7 pages

- Change Abounds FOR Additives: by Sydney MooreNo ratings yetChange Abounds FOR Additives: by Sydney Moore7 pages

- Viscosity Index Improvers For Multi GradNo ratings yetViscosity Index Improvers For Multi Grad8 pages

- RF7801 Automatic Transmission oil package Typical dataNo ratings yetRF7801 Automatic Transmission oil package Typical data7 pages

- Preparation, Characterization, and Evaluation of Some Ashless Detergent-Dispersant Additives For Lubricating Engine OilNo ratings yetPreparation, Characterization, and Evaluation of Some Ashless Detergent-Dispersant Additives For Lubricating Engine Oil10 pages

- 2019-32-0510-Identifying The Limitations of The Hot Tube Test As A Predictor of Lubricant Performance in Small Engine ApplicationsNo ratings yet2019-32-0510-Identifying The Limitations of The Hot Tube Test As A Predictor of Lubricant Performance in Small Engine Applications5 pages

- Lubrizol360 Webinar - Predicting High-Temperature Performance in Motorcycle Engine Oils - Z124No ratings yetLubrizol360 Webinar - Predicting High-Temperature Performance in Motorcycle Engine Oils - Z12449 pages

- Base Oil White Oil Ultra Series Group IIINo ratings yetBase Oil White Oil Ultra Series Group III1 page

- Automatic Transmission Fluids: © 2009 The Lubrizol Corporation 08-27-03 AT100-001No ratings yetAutomatic Transmission Fluids: © 2009 The Lubrizol Corporation 08-27-03 AT100-00130 pages

- Timken Lubricants: Timken Grease Interchange GuideNo ratings yetTimken Lubricants: Timken Grease Interchange Guide2 pages

- LANXESS Lubricant Additive Packages Additin Product Guide - ENNo ratings yetLANXESS Lubricant Additive Packages Additin Product Guide - EN20 pages

- Infineum - Used Oil Elemental Analysistable 1599925859367No ratings yetInfineum - Used Oil Elemental Analysistable 15999258593672 pages

- Additiv 730 Additiv 830 (For Engine Oil) TdsNo ratings yetAdditiv 730 Additiv 830 (For Engine Oil) Tds2 pages

- List of Approved Oils Oil Change Interval 120,000 KMNo ratings yetList of Approved Oils Oil Change Interval 120,000 KM10 pages

- 7 - Preformed Soap As Thickener and EP-Additive For Grease Production100% (1)7 - Preformed Soap As Thickener and EP-Additive For Grease Production10 pages

- Measurement of Extreme Pressure Properties of Fluid Lubricants (Falex Pin and Vee Block Methods)No ratings yetMeasurement of Extreme Pressure Properties of Fluid Lubricants (Falex Pin and Vee Block Methods)10 pages

- BASFBrochure - Selection Guide Lubricant Additives0% (1)BASFBrochure - Selection Guide Lubricant Additives4 pages

- Lubricants in Refrigerant Systems: Tests For Boundary LubricationNo ratings yetLubricants in Refrigerant Systems: Tests For Boundary Lubrication27 pages

- Lubricants For The Manufacturing IndustryNo ratings yetLubricants For The Manufacturing Industry20 pages

- SAE J300 Viscosity Grades Below 20 Grade-SAE Power Trains Fuels and Lubricants-2010No ratings yetSAE J300 Viscosity Grades Below 20 Grade-SAE Power Trains Fuels and Lubricants-201011 pages

- Viscosity Index Improver For Engine Oils: An Experimental StudyNo ratings yetViscosity Index Improver For Engine Oils: An Experimental Study7 pages

- Iso-648 Laboratory Glassware - Single-Volume PipettesNo ratings yetIso-648 Laboratory Glassware - Single-Volume Pipettes18 pages

- L.L.C. EI Sayed: Motor Approval (993/94-100)No ratings yetL.L.C. EI Sayed: Motor Approval (993/94-100)1 page

- STLE 2016 - CMF - Session 6A - K. Hope - Synfluid mPAOs High Viscosity Base OilsNo ratings yetSTLE 2016 - CMF - Session 6A - K. Hope - Synfluid mPAOs High Viscosity Base Oils17 pages

- Allahabad High Court - Court Fee - Revenue - DR - Sushil - Suri - Vs - Harish - Suri - and - 3 - Others - On - 31 - January - 2023 - Full JudgementNo ratings yetAllahabad High Court - Court Fee - Revenue - DR - Sushil - Suri - Vs - Harish - Suri - and - 3 - Others - On - 31 - January - 2023 - Full Judgement13 pages

- SARS ABC of Capital Gains Tax For IndividualsNo ratings yetSARS ABC of Capital Gains Tax For Individuals16 pages

- ShakeOut Recommended Earthquake Safety ActionsNo ratings yetShakeOut Recommended Earthquake Safety Actions2 pages

- Consolidated PPT - Chap 1 and 2 - The Scope and Method of Economics and The Economic Problem - Scarcity and ChoiceNo ratings yetConsolidated PPT - Chap 1 and 2 - The Scope and Method of Economics and The Economic Problem - Scarcity and Choice52 pages

- Truma Watersystems Boiler Bg10 Bge10 Operating enNo ratings yetTruma Watersystems Boiler Bg10 Bge10 Operating en10 pages

- Automotive Engineering - April 2020 - Automotive Engineering - 2020 - Automotive Engineering - Anna's ArchiveNo ratings yetAutomotive Engineering - April 2020 - Automotive Engineering - 2020 - Automotive Engineering - Anna's Archive52 pages

- O Level English Language 1123: Unit 7: Reading A Variety of TextsNo ratings yetO Level English Language 1123: Unit 7: Reading A Variety of Texts3 pages

- Optimised Funds Fairbairn Capital's Investment Frontiers From Old MutualNo ratings yetOptimised Funds Fairbairn Capital's Investment Frontiers From Old Mutual2 pages