Dosage Form Design

Uploaded by

NICOLE ANGELIQUE M. DINOYDosage Form Design

Uploaded by

NICOLE ANGELIQUE M. DINOYDrug Dosage Form Design

Dosage Form ROUTES OF ADMINISTRATION

Dosage forms are meant by which drug 1. Oral

molecules or delivered to sites of action Tablets

within the body to produce desired Immediate-release (IR)

therapeutic effects and minimum adverse Enteric -Coated (EC)

effects Sprinkles & Granules

It is the combination of API and Excipients. Effervescent tablets

API is the chemical compound intended for Orally- Disintegrating (ODTs)

used in treatment and prevention of Controlled or Sustained Release

disease. Sublingual

Excipients are inactive pharmaceutical Capsules

ingredients technological, Hard Gelatin

biopharmaceutical/ or stability reasons. Soft Gelatin

2. Topical / Transdermal

Why Dosage Forms? Transdermal Patch

Safe and convenient delivery of accurate Creams

dosage Ointments

Protection from the atmosphere Gels

Protection from the gastric acid (EC tablet)

Masking bitter, salty, or offensive taste or 3. Parenteral

odor Intravenous

Liquid formulation for insoluble and Subcutaneous

unstable drugs Intradermal Injections

Rate- controlled drug Action Intramuscular Injections

Topical drug action Intraspinal Injections

Drug insertion into body cavity Intrathecal

Drug placement into bloodstream Epidural

For inhalation Therapy 4. Rectal

Suppositories

Rectal ointment & creams

CLASSIFICATION OF DOSAGE FORMS Enemas

Rectal Foams

Immediate 5. Vaginal

Release Release Tablets

rate Suppositories

Modified or Timed-Release Creams

Ointments

6. Ophthalmic / Ocular

Solutions

Ointments

Extended Release Delayed Release Suspensions

Examples

7. Pulmonary

8. Nasal

Controlled Release Sustained Release Targeted

release

State of Dosage form WORK FLOW Of Pre-formulation Studies

1. Solid

Tablets

Capsules

Powders

2. Semi-solids

Creams

Ointments

Gels

3. Liquids

Monophasic

Syrups

Biphasic

Suspension

Emulsions

4. Gas

Nebulized solutions

Aerosols

Packaging

1. Unit Dosage Forms

Tablets

2. Bulk Dosage Forms

Powders

Pre-formulation Consideration

Physical Consideration

WHAT IS NEEDED TO DESIGN A DOSAGE FORM? Microscopic observation

1. Pre- formulation Studies Macroscopic observation

2. Stability Studies Particle size and shape

PRE- FORMULATION STUDIES Solubility

It is defined as the phase of research and Polymorphism

development in which physical and Physical form (crystal/ Amorphous)

chemical properties of drug molecule in Flow properties

order to develop safe, effective and stable Chemical Consideration

dosage form. Hydrolysis

It is the first step in rational dosage form Oxidation

development substances Reduction

It is performed based on dosage forms to Racemization

be developed. Polymerization

OBJECTIVE OF PRE-FORMULATION STUDIES Isomerisation

To establish the physico-chemical Photo stability

parameters of a new drug entity

To determine its kinetic and stability

To establish its compatibility with

common excipients

It provides insights into how drug

products should be processed and

stored to ensure their quality

The purity of the chemical substances is Melting Point depression

essential for its identification as well as for the A characteristic of a pure substance is

evaluation of its chemical, physical, and defined melting point or melting range.

biological properties. If not pure, the substance will exhibit a

depressed melting point.

This phenomenon is commonly used to

Chemical Structures, form and

determine the purity of a drug

Properties reactivity

substances before inclusion in the same

dosage form.

Physical Physical description, Melting point or Freezing point

Properties Particle size, Crystalline Defined as the temperature where the

structure, Melting point, pure liquid and solid exist in

Solubility. equilibrium.

The melting point / range of a drug can be used

Biologic Ability to get a site of as an indicator of purity of chemical substances

properties action, Elicit a biologic (a pure substances would ordinarily be

response characterized by a very sharp melting peak.)

An altered peak or a peak at a different

temperature may be indicative of an

Physical Form adulterated or impure drug.

Before the formulation of a drug substances into a

dosage form, it is essential that it will be chemically and Particle Size

physically characterized. Certain physical and chemical

properties of drug substances are

affected by the particle size distribution,

including drug dissolution rate,

bioavailability, content uniformity,

taste, color and stability.

In addition, properties such as flow

characteristics and sedimentation rates,

among others, are also important

factors related to particle size.

Polymorphism

An important factor on formulation is

the crystal or amorphous form of the

drug substance. Polymorphic forms

usually exhibit different physio-

chemical properties including melting

point and solubility.

Microscopic examination The changes in crystal characteristic can

Microscopic examination of the raw influence bioavailability, chemical and

drug substance is an important step in physical stability, and have important

pre-formulation work. implications in dosage form process

It gives an indication of particle size and functions.

particle size range of the raw materials

as well as the crystal structure.

Solubility Solubility and pH

A drug must possess some aqueous pH is one of the most important

solubility for therapeutic efficacy. factors involved in the

For a drug to enter the systemic formulation process. Two areas

circulation to exert a therapeutic effect, of critical importance are the

it must first be in solution. effects of pH on solubility and

Relativity insoluble compounds often stability.

exhibit incomplete or erratic The effect of pH on solubility is

absorption. critical in the formulation of

If the solubility of the drug substance is liquid dosage forms, from oral

less than desirable, consideration must and topical solutions to

be given to improve its solubility. intravenous solutions and

Solubility and particle size admixtures.

Although solubility is normally Dissolution

considered a physiochemical Dissolution rate can affect the

constant, small increases in solubility onset, intensity, and duration of

can be accomplished by particle size response, and control the overall

reduction. bioavailability of the drug from

the dosage form.

The dissolution rate of drugs

may be increased by decreasing

the drug’s particle size.

It may also be increased by

increasing its solubility in the

diffusion layer. The most

effective means of obtaining

higher dissolution rates is to use

a highly water soluble salt of the

parent substance.

Membrane permeability

To produce a biological

response, the drug molecule

must first cross a biological

membrane.

The biological membrane acts as

a lipid barrier to most drugs and

permits the absorption of lipid

Solubility and pH soluble substances by passive

pH is one of the most important diffusion while lipid insoluble

factors involved in the formulation substances can diffuse across the

process. barrier only with considerable

The effect pf pH on solubility is difficulty

critical in formulation of liquid

dosage forms, from oral and topical

solutions to intravenous solutions

and admixtures.

Partition coefficient

In formulation development, the Stability Studies

octanol-water partition Stability studies conducted in the

coefficient is commonly used it is pre- formulation phase based on

the indication of drug solubility Chemical Consideration.

profile in water and octanol

Following the illustration provided above, it is defined

as

Solid-state of the drug

alone

Solution Phase

with the expected excipients

[P is dependent on the drug concentration only if the

Drug and Drug Product Stability

drug molecules have a tendency to associate in

solution. Higher P value higher permeability and higher

bioavailability]

Physical and chemical stability of

pKa/ Dissociation constants Evaluation pure drug substances important

Extent of ionization has an for pre-formulation.

important effect on the

formulation and

pharmacokinetic parameter of Drug Mechanism of

the drug.

Stability Degradation

The extent of dissociation/

ionization is, in many cases,

highly dependent on the pH of

the medium containing the drug. Hydrolysis

In the pharmacokinetic area, the

extent of ionization of a drug is

an important factor of its extent

of absorption, distribution, and Hydrolysis (solvolysis

process)

elimination.

Dissolution constant or pka is

usually determined by

potentiometric titration.

Susceptible to he

(drug) molecules

hydrolytic process :

interact with water

esters, substituted

molecule to yield

amides, lactones, and

breakdown product.

lactams.

Oxidation Decarboxylation

Is a chemical reaction that

removes a carboxyl group and

release carbon dioxide (CO2).

Loss of electrons from Usually, decomposition of

an atom or molecule.

RCOOH

aldehyde, alcohols,

phenols, sugars,

Free radicals

alkaloids &

unsaturated fat & oils.

Racemization

Racemization refers to partial

conversion of one enantiomer Deamination

into another resulting in loss of Removal of nitrogen containing

biological activity. amino group from organic

Conversion of optically active amine.

compound into inactive

compound.

It affects solubility, dissolution,

absorption and bioavailability of

drug.

L- epinephrine is 15-20 times

more active than D-form while

racemic mixture has half of

inactivity than L-form.

Polymerization

Any process in which relatively

small molecules, called

monomers, combine chemically

to produce a very large chain like

or net work molecule, called a

polymer. The monomers

molecules may be all alike, or

they may represent two, three, Drug Instability Detected by

or more different compounds. Physical Appearance

Color

Odor

Taste

Texture of the

formulation

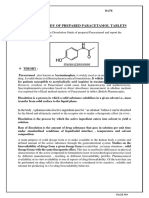

Fig. Paraformaldehyde

Oxidizable drugs Stabilized in Stability Testing

Formulation

1.) Accelerated 2.) Short term 3.) Long term

Exclusion Inclusion Stability accelerated stability studies

Oxygen Maintain a testing/Stress studies

favorable pH Testing

Oxidizing agents Antioxidants

Trace metals Chelating agents When real time Determines most Product is

Light Buffering agents data is stable of the subjected to

unavailable it is proposed different

Heat

performed for formulations for climatic zones

Other chemical shelf life a drug product

catalysis (temp. &

determination. lesser temp and

Accelerated humidity. humidity)

stability study is nationally &

Hydrolysable Drugs Stabilized in subjecting the internationally

Formulation. product to an predicted from

Reduction For

elevated level of the data

For certain

and the unstable antibiotic hydrolysable stress like generated from

elimination In Liquid In certain drugs the pH

of water for preparations injectable drugs, when an

of optimum

controlled continuing

aqueous

solid products

preparation is

stability. changes in stability studies

preparation

desired temperature or 12 months

humidity and

minimum.

By applying Water Anhydrous Use Dry form Between light.

a water replaced or vegetable

proof reduced in oils may be for pH 5 and

protective the used as the reconstitution 6, Use of

coating. formulation. drug's buffering Study Storage Minimum time

solvent agents.

condition period covered

By Use of

by data at

Powder

enclosing substitute for submission

and liquid-

maintaining injection Long term 25°C ± 2°C / 12 months

glycerin,

the drug in

propylene 60% ± 5% r.h. or

tightly

closed glycol, and 30°C ± 2°C /

containers. alcohol.

65% ± 5% r.h.

Intermediate 30°C ± 2°C / 6 months

65% ± 5% r.h.

Trace metals in drug stabilized by completing or Accelerated 40°C ± 2°C / 6 months

binding metal by using specialized agents 75% ± 5% r.h.

(chelating agents- Cadisod edetate & EDTA)

Container and solvent are source of difficulty in

preparing stable solutions of oxidizable drugs

which is eliminated by purification of source of

contaminant

Light catalyst to oxidation reactions

preparations packed in light resistant or opaque

containers can enhance stability.

You might also like

- Unit 2 Solid and Liquid Dosage Forms: StructureNo ratings yetUnit 2 Solid and Liquid Dosage Forms: Structure19 pages

- Scope of Pharmacy Education: A Concise Presentation byNo ratings yetScope of Pharmacy Education: A Concise Presentation by26 pages

- Cytotoxic Drugs: Pharm. Dr. Ezekiel EfeobhokhanNo ratings yetCytotoxic Drugs: Pharm. Dr. Ezekiel Efeobhokhan24 pages

- Novel Drug Delivery System Thakur Publication B Pharm 7th Semester-CompressedNo ratings yetNovel Drug Delivery System Thakur Publication B Pharm 7th Semester-Compressed114 pages

- Microspheres: BY, Divya Thakur, Mpharmacy (I.P), 1600-4P-1304No ratings yetMicrospheres: BY, Divya Thakur, Mpharmacy (I.P), 1600-4P-130432 pages

- THEORIES OF DISPERSION AND PHARMACEUTICAL DISPERSION(EMULSIONNo ratings yetTHEORIES OF DISPERSION AND PHARMACEUTICAL DISPERSION(EMULSION34 pages

- Pharmaceutical Dosage Forms and CalculationNo ratings yetPharmaceutical Dosage Forms and Calculation3 pages

- Prescription Handelling at Retail Level and Record KeepingNo ratings yetPrescription Handelling at Retail Level and Record Keeping24 pages

- Formulation & Evaluation of Sustained Release Microsphere of PropanololNo ratings yetFormulation & Evaluation of Sustained Release Microsphere of Propanolol11 pages

- Pharmaceutical Technology Lecture-12 - Dextrose Based SyrupNo ratings yetPharmaceutical Technology Lecture-12 - Dextrose Based Syrup21 pages

- Pharmaceutics-Practical-II-Lab-Manual-FinalNo ratings yetPharmaceutics-Practical-II-Lab-Manual-Final52 pages

- Micellar Solubilization: By:-Aakashsoni M.Pharma I Sem. Delhi Pharmaceutical Sciences and Research UniversityNo ratings yetMicellar Solubilization: By:-Aakashsoni M.Pharma I Sem. Delhi Pharmaceutical Sciences and Research University16 pages

- 1-En-Introduction To Pharmaceutical Technology and Mixing100% (1)1-En-Introduction To Pharmaceutical Technology and Mixing72 pages

- Introduction To Pharmacokinetics PharmacodynamicsNo ratings yetIntroduction To Pharmacokinetics Pharmacodynamics28 pages

- Adrenergic Agonist & Antagonist: - Guide: DR R K Solanki Sir DR Neelam Mam DR Kailash MittalNo ratings yetAdrenergic Agonist & Antagonist: - Guide: DR R K Solanki Sir DR Neelam Mam DR Kailash Mittal83 pages

- Feedback Regulated Drug Delivery SystemNo ratings yetFeedback Regulated Drug Delivery System17 pages

- Recent Advancement in Drug Technology1 ChabgesNo ratings yetRecent Advancement in Drug Technology1 Chabges45 pages

- Structural Classification of Drugs: A Quick Reference GuideFrom EverandStructural Classification of Drugs: A Quick Reference GuideNo ratings yet

- Exercises in Organic Synthesis Based on Synthetic DrugsFrom EverandExercises in Organic Synthesis Based on Synthetic DrugsNo ratings yet

- Extraction of Vesivirus Rna: 1. Prepseq Nucleic Acid Extraction KitNo ratings yetExtraction of Vesivirus Rna: 1. Prepseq Nucleic Acid Extraction Kit5 pages

- Color and Chemical Constitution of Natural Dye Henna (Lawsonia Inermis L) and Its Application in The Coloration of TextilesNo ratings yetColor and Chemical Constitution of Natural Dye Henna (Lawsonia Inermis L) and Its Application in The Coloration of Textiles9 pages

- Multiple Choice Questions (MCQ) Topic Quiz 4.2 Alcohols, Haloalkanes and AnalysisNo ratings yetMultiple Choice Questions (MCQ) Topic Quiz 4.2 Alcohols, Haloalkanes and Analysis11 pages

- The Skin Barrier and Moisturization: Function, Disruption, and Mechanisms of RepairNo ratings yetThe Skin Barrier and Moisturization: Function, Disruption, and Mechanisms of Repair12 pages

- Organic Farming: Submitted To: Submitted byNo ratings yetOrganic Farming: Submitted To: Submitted by17 pages

- (eBook PDF) Organic Chemistry 7th Edition by William H. Brown download pdf100% (1)(eBook PDF) Organic Chemistry 7th Edition by William H. Brown download pdf50 pages

- TCP I Two Marks Question With Answer Unit IiNo ratings yetTCP I Two Marks Question With Answer Unit Ii12 pages

- Difference Between Aerobic and Anaerobic Respiration: April 2017No ratings yetDifference Between Aerobic and Anaerobic Respiration: April 201712 pages

- AQA AS Chemistry 13 practice question answersNo ratings yetAQA AS Chemistry 13 practice question answers3 pages

- Chemistry Option F: Food Dyes and PigmentsNo ratings yetChemistry Option F: Food Dyes and Pigments2 pages

- AGM 301-Agricultural Microbiology (1+1)No ratings yetAGM 301-Agricultural Microbiology (1+1)24 pages

- Chemical Compatibility Results From Cole-Parmer IndiaNo ratings yetChemical Compatibility Results From Cole-Parmer India2 pages