u1-5

Uploaded by

Goutham vignesh Ju1-5

Uploaded by

Goutham vignesh JED19P31 - PRODUCT LIFECYCLE MANAGEMENT

UNIT-I HISTORY, CONCEPTS AND TERMINOLOGY OF PLM

Product?

products that can be owned,

Tangible

(Goods)

traded, and distributed to different

places at different times without

changing their identity

What is a Intangible

piece of software, a

product? piece of knowledge or an

algorithm or a formula

Experience of

Services

something

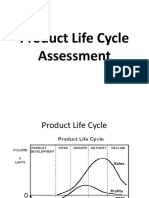

PLM vs PLM(Marketing)

PLM – Product Lifecycle Management

Describes engineering aspect of the product

PLCM – Product Life cycle Management (marketing)

Refers to commercial management of life of a product w.r.t costs and sales measures

Different views of PLM

Engineering Data Management (EDM),

Product Data Management (PDM)

Collaborative Product Definition Management (cPDm)

Collaborative Product Commerce (CPC)

Product Lifecycle Management (PLM).

EDM and then PDM emerged in the late 1980s as engineers in the manufacturing industries

keep track of the growing volumes of design files generated by CAD

EDM (currently the appropriate acronym would be PLM)

EDM is a systematic way to design, manage, direct, and control all the information needed

to document the product through its entire lifespan: development, planning, design, production,

and use.

cPDm is another American acronym for product lifecycle management

It is a business approach to adapt electronic systems to the management and definition of

product data in the company network (including the customers and suppliers) for the whole life

cycle of the product

CPC - especially to the adoption of the principles of product lifecycle management in

networked businesses, utilizing the possibilities brought by the Internet.

Here too, cooperation between customers, subcontractors, suppliers and partners is

considered, with the product as the factor connecting the whole network

The term CPC is used mostly by companies and consultant organizations that deliver

PLM/PDM software

CPC Example

International consultant organization Accenture, according to their Internet home page, defines

CPC as supporting three key areas of operation in companies,

Processes of product development

Internal cooperation

External cooperation

Product Data Management?

PDM is mainly a set of tools and methods aimed at efficiently managing product data,

PDM allowed

to standardize items,

to store and control document files,

to maintain BOM’s,

to control item,

BOM and document revision levels,

and immediately to see relationships between parts and assemblies.

What is PLM?

Product Lifecycle management (PLM) is the process of managing the entire lifecycle of a

product from its,

CONCEPTION

through

DESIGN AND MANUFACTURE

to

SERVICE AND DISPOSAL

What is a good PLM?

A good PLM-concept is never static; it keeps evolving in tune with the business and its

requirements.

PLM/PDM tools

Oracle Agile

Teamcenter

PLM

Arena Windchill

SAP PLM ENOVIA

Aras PLM

Scope of PLM

PLM is a “holistic business concept” developed

to manage a product and its lifecycle including not only items, documents, and BOM’s,

but also

o analysis results,

o test specifications,

o environmental component information,

o quality standards,

o engineering requirements,

o change orders,

o Manufacturing procedures,

o product performance information,

o component suppliers,

o ETCETERAS….

1. Managing a well-structured and valuable Product Portfolio

2. Maximising the financial return from the Product Portfolio

3. Providing control and visibility over products throughout the lifecycle

4. Managing products across the lifecycle

5. Managing product development, support and disposal projects effectively

6. Managing feedback about products from customers, products, field engineers and the

market

7. Enabling collaborative work with design and supply chain partners, and with customers

8. Managing product-related processes so that they are coherent, joined-up, effective and lean

9. Capturing, securely managing, and maintaining the integrity of product definition

information. Making it available where it’s needed, when it’s needed

10. Knowing the exact characteristics, both technical and financial, of a product throughout its

lifecycle

Modern PLM system capabilities include

o workflow,

o program management,

o and project control features that standardize, automate,

o and speed up product management operations.

Web-based systems enable companies easily to connect their globally

People Centric PLM targets the design phase

PLM – Background

Benefits

Reduced time to market

Improved product quality

Reduced prototyping costs

More accurate and timely request for quote generation

Ability to quickly identify potential sales opportunities and revenue contributions

Savings through reuse of original data

A framework for product optimization

Reduced waste

Increase product revenues by 30% and decrease product maintenance costs by 50%.

Area of Benefit Examples of Benefits

Financial increase revenue with earlier market introduction; reduce

Performance product development costs

Time Reduction reduce project overrun time; reduce engineering change time

Quality reduce manufacturing process defects; reduce the number of

Improvement returns; reduce the number of customer complaints

increase the innovation rate; increase the part reuse factor;

Business

increase product traceability; ensure 100% configuration

Improvement

conformity

Areas of PLM

The five primary areas are

1. Systems Engineering

2. Product and portfolio management

3. Product design

4. Manufacturing process management

5. Product data management

Phases of Product Lifecycle

1. Imagine

2. Define

3. Realise

4. Use/Support

5. Retire/Dispose

BEGINNING OF LIFE MIDDLE OF LIFE END OF LIFE

(Imagine/Define/Realise) (Support/Maintain/Use (Retire/Dispose)

1. During the ideation phase, the product is just an idea in people’s heads.

2. During the definition phase, the ideas are being converted into a detailed description.

3. By the end of the realisation phase, the product exists in its final form (for example, as a

car) in which it can be used by a customer.

4. During the use/support phase, the product is with the customer who is using it.

5. Eventually the product gets to a final phase in which it’s no longer useful. It’s retired by

the company, and disposed of by the customer.

In each of these five phases, the product is in a different state

Problems across the product lifecycle

Imagine Define Realise Support/Use Retire/Recycle

Projects late/ Incorrect

Ideas pirated Pollution costs Upgrades ignored

failing identification

Poor factory

Lack of ideas Costs too high Missing applications Poor documentation

layout

Uncontrolled Poor

Ideas lost Scrap Low recycle rate

changes communication

Suppression of

Unclear processes Rework Data out of control Materials wasted

ideas

Missing

Needs not clear Costly prototypes Little feedback High disposal costs

applications

Supplier

Culture of sterility Design faults Customers lost Fines

problems

Application High material

Failure punished Liability costs No training

Islands costs

Long time to

Bureaucracy Excess inventory Missing services Lack of control

market

Limited part re-

Priority, #1 CYA Data silos High service costs Missing applications

use

Unknown cost Culture of risk Slow ramp-up Processes unclear Processes undefined

Project status

No training Safety problems Product recalls Lack of procedures

vague

No process Wrong data

Too many projects Product failures Costly disassembly

defined versions

Managing the product across lifecycle

1. WHEN IT'S AN IDEA. For example, making sure the product idea isn’t lost or

misunderstood

2. WHEN IT'S BEING DEFINED. For example, making sure that the development project

for the product meets its objectives

3. WHEN IT'S BEING REALISED. For example, making sure the correct version of the

definition is used during production

4. WHEN IT'S IN USE. For example, making sure the product is correctly maintained, taking

account of its serial number, production date, previous upgrades, changes in the market and

technical evolution

5. WHEN IT'S BEING DISPOSED OF. For example, making sure poisonous components

and toxic waste from the product don’t get anywhere near sources of drinking water

Some reasons for things going wrong with products

PROBLEM AREA ISSUE(S)

Products Incorrectly, or unclearly, defined products

Data out of control; data in silos; different definitions of data; incorrectly structured

Data

data

Processes Processes not defined; unclear processes; conflicting processes

Islands of Automation; missing applications, ineffective application interfaces;

Applications

unaligned applications leading to manual data re-entry and errors

Projects Project status vague; unclear project objectives; too many projects

Equipment Machines and software licences under-utilised or not used

People Specific skills missing; lack of training

Working methods not defined; Differences between the organisational structures on

Organisation

different sites

Managing Product

A product must be managed in all phases of the lifecycle to make sure that everything works

well, and that the product makes good money for the company

Pre-PLM Environment

Within a company, the responsibility for the product is often different at different phases

of the lifecycle.

At one time it may be with Marketing, at other times with Engineering or Service.

Maintaining a common coherent approach among these organisations, which may have

different objectives, working methods and applications, can be difficult and time-

consuming.

The issues are then no longer just cross-functional but also cross-enterprise

Pre-PLM Environment Three Letter Acronym (TLA)

ABC BPM CAD CAE

CAM CM DFA DFM

DFMA DFE DFSS DMU ECM EDM EMI ERP

FA FEA FMEA GT HQ ISO 9000 ISO 14000 JIT

KPI LCA MM MRP NPD NPI NPDI OD

PBS PDM QFD R&D RPS STEP S&G TQM

TRIZ UML VA VE

WBS XML YTD ZB

Alphabet soup for managing a product

Each of these helped manage a product at a different moment in its life.

Each had technical objectives, not business objectives.

With this piecemeal approach, organisations didn’t manage products in a joined-up way

across the product lifecycle.

For example, product development and product support were often carried out in different

parts of the organisation even though they addressed the same products

The subject of how products were managed across the lifecycle hadn’t been explicitly

addressed by company management.

o It wasn’t planned.

o It wasn’t documented.

In such a situation, often nobody in the company could describe in detail how the products

were managed throughout the lifecycle.

The end result was reduced revenues and higher costs.

PLM Grid

PLM is holistic

Products Services Structures Activities Processes

People Equipment

Skills PLM Standards

Applications Practices

Systems Data Information Knowledge Techniques

Before PLM, activities were unconnected

Product Development Product Support Project Portfolio Management Disassembly

Product Infancy Developer sustainable Development Product Liability

CAD, PDM Product Definition Product End-of-Life Customers

Development Product Development Product Portfolio Management Environment

Assembly Innovation Disposal Mature products

Product Development and Product Support

Product Infancy and Product End-of-Life

CAD, PDM and Project Portfolio Management

Product Development and Product Disposal

Product Assembly and Product Disassembly

Product Development and Product Liability

Product Developers and Customers

Product Definition and Environmental Issues

Product Development and Sustainable Development

Product Innovation and Mature Products

Project Portfolio Management and Product Portfolio Management

KPIs in the PLM environment

number of new products per year % of product data in electronic form cost of rework ($)

cost of IS as % of company sales new product revenue (% of total) number of patents

Return On Innovation % of business processes defined number of customers

number of NPD projects

value of product portfolio ($) Time To Market (months)

completed per year

number of defects per product

R&D spend (% of revenues) level of part reuse

family

service revenue ($, or % of total) recall costs ($) % products recycled

Importance of PLM

NEW TECHNOLOGIES

Mechatronics

World Wide Web

REGULATIONS MARKET

Health New Customers

Environment Product

THE PRODUCT Customisation

Safety New Markets

COMPETITION

New C ompetitors

Low-cost Competitors

PLM Initiative

The PLM Initiative of a company is an initiative with two objectives:

To improve the product-related performance of the company

To put in place, or to improve, the capability to manage products across their

lifecycles

Main steps in a PLM Initiative

Launch the PLM Initiative

Carry out a Feasibility Study

Understand the Current Situation

Develop the PLM Vision and Strategy

Develop the PLM Implementation Strategy

Develop the PLM Implementation Plan

Implement the Plan

Typical activities in a PLM Initiative

plan the Initiative report progress map the current process manage the Planning phase

define product data define new business

select team members migrate product data

KPIs processes

create workflows manage project risks mentor executives align change expectations

model the future

define new roles plan roll-out strategy maintain PLM applications

process

coach Team Members define Initiative KPIs plan roll-out activities develop a process glossary

implement a PDM

define process KPIs plan training activities define Use Cases

system

plan OCM activities harmonise applications restructure product data manage Initiative start-up

develop an OCM communicate about

select a PDM system create new job descriptions

glossary changes

All PLM Initiatives are different. There are thousands of different PLM Initiatives in thousands

of companies.

A New Way of Thinking

Before PLM With PLM

Think Product Manufacturing Think Product Lifecycle

Think vertically about the company Think horizontal

Think functionally about the company Think lifecycle

Think about one activity of the company Think about several activities

Think product development Think cradle-to-grave

Think Focus on the customer Think Focus on the product and then the customer

Think Listen to the Voice of the Customer Think Listen to the Voice of the Product

Think going forward in time Think forwards and backwards

Think Customer Survey Think Customer Involvement

Think product portfolio & project portfolio Think Integrated Portfolio

Think bottom-up, starting with a part Think top-down starting with the portfolio

Think about the product lifecycle bit-by-bit Think about PLM in a joined-up, holistic way

Think PLM is for the techies Think PLM is a top management issue

Think profit Think profit and planet

Think ourProcesses Think standard processes

Think ourData Think standard information

Think ourApplications Think standard applications

Think Product Manufacturing to Think Product Lifecycle

Thinking PLM, it’s clear that,

in developed countries, companies’ future profits won’t come from Manufacturing and

Assembly of commodity products.

Companies where wage costs are 10% will be able to carry out those Manufacturing and

Assembly activities at a much lower cost

Think vertically about the company to Think horizontal

Before PLM,

when thinking about a company in simple terms, people broke it up into functional

departments. with reference to those functions

Thinking PLM,

people view the company in terms of product lines.

They look to build the best design chain and supply chain for that product line

Think functionally about the company to Think lifecycle

Before PLM,

people thought functionally about the company.

A Marketing VP, an Engineering VP and a Manufacturing VP would report to the CEO.

Managers of product lines would report in through a matrix.

Thinking PLM,

people first think about the product lifecycle.

A Chief Product Officer (CPO) has the responsibility for all the products across the

lifecycle.

The CPO reports to the CEO.

So do the Chief Financial Officer (CFO) and the Chief Information Officer (CIO).

Product Managers report to the CPO.

Think about one activity of the company to Think about several activities

Before PLM,

people would think about one activity in a company at a time.

In the Engineering Department, without considering the needs of other people in the

lifecycle, design engineers would buy new application software to design products faster

With PLM,

people think about more than one activity at a time.

They think about the product across its lifecycle.

Engineers designing a product take account of how it will be manufactured.

And how it will be disassembled and recycled.

Think product development to Think cradle-to-grave

Before PLM,

Product development, in particular, was often seen as a separate island, disconnected

from the other activities.

Design engineers seemed to have problems communicating with people in other

functions, so were left to work alone.

With PLM,

people think about the entire product lifecycle, from cradle to grave.

Product development is one of many activities in the lifecycle, and is closely integrated

with the others.

Design engineers talk to people in other functions

Think Focus on the customer to Think Focus on the product and then the customer

Before PLM,

the rule was ‘‘focus on the customer’’.

With PLM,

the rule is ‘‘first focus on the product’’, then focus on the customer.

Customers buy great products.

they won’t get a sale without a competitive product.

Think Listen to the Voice of the Customer to Think Listen to the Voice of the Product

Before PLM,

the rule was listen to the ‘‘Voice of the Customer’’.

With PLM,

the rule is ‘‘listen to the Voice of the Product as soon as possible’’.

Get the product to report back about how it’s working.

And, of course, don’t forget to listen to the ‘‘Voice of the Customer’’

Think going forward in time to Think forwards and backwards

Before PLM,

people thought towards the future: first came product development, then manufacturing,

then support.

Time goes forward.

One thing comes after another.

With PLM,

not only are there flows, such as time, going forwards.

There are also flows going backwards.

Information comes back from product operation to be used in product development.

Think Customer Survey to Think Customer Involvement

Before PLM,

people would carry out a Customer Survey to find out what customers thought of existing

and future products.

With PLM,

people think Customer Involvement. Using technologies such as

o mobile telephony,

o GPS,

o Radio Frequency Identification (RFID) technology

o Web,

and they exchange information directly with a customer who is using the product

Think product portfolio & project portfolio to Think Integrated Portfolio

Before PLM,

people in Marketing and Sales would refer to the product portfolio.

This was the portfolio of existing products.

Meanwhile, people in Engineering would refer to the project portfolio.

This was the portfolio of new products in the pipeline.

With PLM,

everyone in the lifecycle refers to the Integrated Portfolio which contains both the

existing products and those under development

Think bottom-up, starting with a part to Think top-down starting with the portfolio

Before PLM,

people would think bottom-up, starting with parts and building up to the product.

After parts were developed, it would be found that they didn’t fit into assemblies.

So they were redesigned

With PLM,

people start by thinking about the Integrated Portfolio, then work down through product

families, platforms, and modules, to products, and then to parts.

PDM systems manage the information about a product across its lifecycle.

Think about the product lifecycle bit-by-bit to Think about PLM in a joined-up, holistic

way

Before PLM,

the many product-related issues weren’t considered together.

For example, Product Recall, Product Development and Product Liability would be

addressed separately and independently.

With PLM,

all the product-related issues are united under PLM and are addressed together in a

joined-up way.

The approach is holistic.

PLM is seen as the way to address all the product-related issues.

Think PLM is for the techies to Think PLM is a top management issue

Before PLM,

product-related issues weren’t considered to be a subject for management.

With PLM,

top managers understand and can formulate the need for effective product lifecycle

management.

They define the key metrics.

And how the activity will be managed.

Think profit to Think profit and planet

Before PLM,

companies often put profit before the planet.

They fouled the air, the water and the land

With PLM,

companies think profit and planet.

They take more account of nonfinancial issues, such as the environment, social issues,

health, education and sustainable development.

Think our Processes data, applications to Think standard Processes, information,

applications

Before PLM,

companies thought about our Processes, our Data, our Applications.

In the extended enterprise environment, each inter-organisation interface was a source of

chaos, adding costs and slowing down lifecycle activities.

With PLM,

companies think of the standard processes, standard data and standard systems

that they, and their numerous suppliers, customers, and partners in the extended

enterprise environment,

can use to save an enormous amount of time and money.

Product data or product information

Product data refers to information (broadly related to the product)

Product data can be roughly divided into

o Definition data of the product

o Life cycle data of the product

o Metadata that describes the product and lifecycle data

The definition data of the product

determines physical and/or functional properties of the product

o i.e. form, fit and function of the product

describes the properties of the product

o from the viewpoint of a certain party (e.g. customer or producer)

o and connects the information to the interpretation of the party in question.

This includes very exact technical data as well as abstract and conceptual information

about the product and related information.

The wide spectrum of information and the difference in the contents of definition data can easily

cause problems, owing to different interpretations and contexts.

The life cycle data of the product

is always connected to the product and the stage of the product or order-delivery process.

This group of information is connected to technological research, design and to the

production, use, maintenance, recycling, and destruction of the product, and possibly to

the official regulations connected with the product.

The Meta data

it describes the product data:

o what kind of information it is,

o where it is located,

o in which databank,

o who has recorded it,

o and where and when it can be accessed?

Product lifecycle management concept

The product lifecycle management concept covers at least the following areas:

o Terms and abbreviations used in this field (definition of product, lifecycle,

lifecycle phases, etc.)

o Product information models and product models

o Definition of products and product-related information objects (items,

structures, product-related documents, definition of product information, etc.)

o Product lifecycle management practices and principles used and applied in the

company (how products are managed throughout their lifecycle, identification of

information management principles such as versioning principles, information

statuses, etc.)

o Product management related processes

Product information management processes

o Instructions on how to apply the concept in everyday business

The core processes and functional verticals of an industrial enterprise

• It shows how the core processes are cross functional and cross organizational.

PLM system is positioned as a common and central databank within the field of operation

of the process oriented manufacturing enterprise

Product lifecycle management entities

PLM entities include

1. Item management

2. Product structure management and maintenance

3. User privilege management

4. Maintenance of the state or status of documents and items

5. Information retrieval

6. Change management

7. Configuration management

8. The management of tasks (messages), a k a workflow management

9. File/document management

10. Information loss during updating is avoided

11. Backup management

12. History/System log

13. File vault (electronic vault)

System architecture

Commercial PLM systems typically have many features in common.

All systems contain certain features, functions and techniques, which are functionally

identical irrespective of the system. Such system-independent functional units include:

o The file vault

o The metadata base

o The application

Example of a PLM system architecture

High Level Agile PLM Architecture

Understanding the PLM architecture

We can divide the main components of a PLM architecture stack into three main

categories:

PLM applications, core systems and business intelligence platforms.

o Core systems consolidate and enrich the data that PLM applications create.

o PLM applications are usually discipline- specific and involve 3D modelling and

simulations.

o Business intelligence platforms are used to present data and extract insights.

Are all the PLM Architecture the same?

There are considerable differences between various systems and system architectures.

The reasons for these differences are:

o The properties and requirements brought by differences in the scope and

scalability of the systems.

o The different types of functions required within different branches of industry due

to different priorities and emphases.

o System suppliers approach the whole PLM concept from different directions.

Different applications can usually be connected to the PLM system by links of different levels.

The following four different levels are distinguished:

Encapsulation: Reference information for the file identifies an application that

can open it (e.g. e-mail attachments or files selected in Windows Explorer)

Information exchange between systems: File-based data transfer

Database integration: Different systems use a common databank

Platform or middleware integration or EAI (enterprise application integration)

use of a separate software layer (middleware) that transmits and moves the

required information between different systems

UNIT-II PLM/PDM FUNCTIONS AND FEATURES

Functionality of the systems

How do the systems cope at a practical level with

o set objectives,

o staff wishes and

o the demands of the business environment?

This success depends on several factors, but

o mainly on how well the user organization has defined its own needs and goals

o and on how the commercial software available on the market is fitted with these

demands.

In the following, let us take a look at the

o Properties of product lifecycle management systems and their development

potential in their deployment.

PLM entities include

Item management

Product structure management and maintenance

User privilege management

Maintenance of the state or status of documents and items

Information retrieval

Change management

Configuration management

The management of tasks (messages), a k a workflow management

File/document management

Information loss during updating is avoided

Backup management

History/System log

File vault (electronic vault)

1. Management of the status/state of files

Check out puts a flag in PLM Software that a file has been downloaded for modification

and no one else may modify the file while it is checked out, Well they can but their

changes would be outdated after you check in.

Check in is the process of uploading your modified checked out files back to the

common space on the PLM Software so others may see your changes, it also removes the

flag so others may check now the file for further changes

These functions are usually called the check out and check in functions of the system.

The designer prepares a CAD drawing, completes the planning work on his own PC or

workstation and saves the finished file to the management of the PLM system.

He notifies the system of the attribute information (Meta data), related to the file so that it

can be classified in the desired standard way and placed in a suitable location in the

system.

Alternatively, this attribute information can be retrieved from the heading field of the

CAD drawing and automatically copied to metadata.

2. Creating an item

The version is given a number or letter mark, for example A, B, C, D.

Usually only checked and released files are recorded in the file vault, in which case the

PLM system keeps a log about the history of events related to the document,

o in other words the system traces the items and documents for:

Viewing

Copying

Changes

Commenting

ECR (Engineering Change Request)

ECO (Engineering Change Order)

Printing

An object version is composed of two elements: the character to the left of the decimal is

the revision, and the character to the right of the decimal is the iteration.

3. Distribution management

Approved documents are distributed in a process utilizing workflows.

The PLM system takes care of the distribution automatically according to the workflow

processes and principles defined to the software.

The product structure allows other related documentation to be enclosed with a document

when a reference is needed.

This helps PLM system users to handle larger amounts of information when necessary.

4. Searching and browsing information

Information searches are made possible through the classification of the information

and are facilitated by creating attributes or help information, which describes each

item and helps the system to analyze the information on each item (e.g. document,

component, etc.) in the system.

Engineers expend 15–40% of their working hours in searching and retrieving routine

information

What is the status of each drawing in a certain project?

What has changed in a certain document? Who made the change and when?

What changes have been made in documents related to a given project within

the last two months?

List all the resistors used in production, of which the resistance is greater than

5 Ω but less than 10 Ω

List all allowed suppliers for 20-Ω resistor RES123456

Using Simple Search

Using Advanced Search

Using Advanced Search - Type Section

Using Advanced Search - Context Section

Using Advanced Search - Criteria Section

Using Advanced Search - Nested Queries (AND , OR)

Using Advanced Search - Related Object Search

Advanced Search Report Template

Search Results Table

Faceted Search Results

5. The management and maintenance of product structures

Some Properties of

o Version management,

o structural presentation of information,

o Change management, as well as

o configuration management,

are typically based on product structure management

Same product structure is examined from different viewpoint – in different views – in

different circumstances.

Product structure from the engineering point of view.

Bicycle

Tire Body Saddle Handlebar

Fender Pedals Chain Stickers

Product structure from the manufacturing point of view.

Bicycle

Fender Tire Saddle Body Handlebar Stickers

Pedals

Chain

Modern PLM can handle several product structures for the same product. However, can

become impossible in practice.

Complex products, consisting of thousands of components, become nightmares if

information is maintained at too exact a level, so a suitable level of precision should be

defined beforehand.

Attribute information can be of three kinds:

o Individual product based information such as the serial number of a sourced

component in a certain product

o Generic – regarding generic products, product, assemblage, parts

o User-specific – remarks and notes

Attribute information for the product structure.

Properties of product lifecycle management systems

Management of the status/state of files

Creating an item

Distribution management

Searching and browsing information

The management and maintenance of product structures

6. Management of changes in documents, items and structures (Change Management)

It Provides

o Change processes for products in all those parts of the organization

o Product process traceability for engineering changes made to the design

The change processes usually resemble the previously described management item status.

The change management tool brings

o Controlled changes – the change process takes place in controlled manner.

o Information on completed and forthcoming changes – the information

distribution tool can be e-mail, for example.

o Electronic system – streamlining and significantly accelerating the change

processes.

o Well-controlled and timed changes to items already in distribution and

production (components/documents) become possible in a wide extent.

o Relations between the various pieces of product information are retained in

change situations. For example, the impact of any design change to a sub-

assembly in all products

The reason for the change can be,

o a perceived mistake in the design,

o an idea for a better functioning solution, or

o customer demand.

The person presenting the ECR defines the subject of the change, the items affected by

the change, and a description of the reasons for the change.

An ECR can contain valid electric document with comments and redlining.

The ECR is delivered to the persons responsible for the changes

The change can be carried out without any change requests, i.e. the ECO is made directly

Product structure and version history of the bicycle

7. The transfer of files and file type conversions

User or reader of the file does not need to know its actual location because the usage

environment can be LAN, WAN or the Internet.

The system fetches the file, converts it, and automatically opens it in a suitable

application.

The information has been often recorded in a general standard format (for ex PDF) for

examination and viewing.

Conversions of file type or saving format often arise from the use of separate CAD and

CAM programs.

8. Communication and management of tasks or messages

It form a foundation for Concurrent Engineering.

All its users get the relevant information about all those actions.

The system provides a communication forum for daily working.

9. Adopt PLM

One can adapt PLM systems to the management of (raster) image information.

Companies often have a large archive of paper drawings and paper documents from old

manufactured and maintained products, and from production devices and facilities.

These can be easily scanned into electronic form and the management of the scanned

information can be moved to PLM systems.

This greatly improves the controllability of the archives and the distribution of the

documentation.

PRODUCT DEVELOPMENT AND ENGINEERING

PRODUCTION

AFTER SALES

SALES AND MARKETING

SUB-CONTRACTING

SOURCING AND PROCUREMENT

PLM SOLUTIONS

Use of product lifecycle management systems in different organization verticals

Used by a wide variety of organizations, including companies, communities, and

government institutions.

Main stress in product lifecycle management systems has long been in the area of

planning, design and engineering functions for the manufacturing industry

However evolution of PLM system has increased their utilization also in sales, marketing,

and, especially, after sales.

Information about components and parts to be sourced and procured is delivered from the

product design to sourcing and procurement.

Applicable configuration rules and structures are also usually communicated very early

from design to sales

Changes to the product design are transferred to production,

Product and spare part documentation to after sales, during the maintenance phase of the

life cycle.

Product development and engineering

Management of documents - so that the desired information is easily available and

quickly distributed

o This increases the effectiveness of the engineering and reduce mistakes.

o Functional change management is also an essential part of the flexible

engineering organization,

Right information about changes goes to production or to the contracting parties

involved.

The third general task in this area is to ensure the updating of the right document version

Production or manufacturing

It has often been claimed that the possibilities for utilizing PLM systems in production

are limited.

Interface b/w engineering and production can be quite problematic from the

organizational, geographical and esp from the information flow points of view.

Change management tool – inform changes

Integrated production – integrate the different manufacturing systems with the

engineering tools.

After sales

Significance of this business has increased quite noticeably.

When products develop quickly, new product versions are always appearing on the

market. This sets great demands on spare part sales, etcetera..

In global markets, maintenance services are often offered by local contracting parties and

they must have secure access to information.

information PULL – distribution functioning on the pulling principle: people finding and

retrieving the information they need.

Sales and marketing

Modular customer-specific product configurations are always created with the help of

preset configuration rules

Accelerates the creation of tenders, because the necessary information can be quickly

accessed.

When customized products are sold to customers, the product configurations are built by

choosing from the features wanted by the customer and from property alternatives

available in the sales configurator so that the product matches the wishes of the customer.

o meets the customer’s requirements

o Supplier has a faultless product structure

Sub-contracting (OEM)

The needs of engineering sub-contracting naturally differ from those of manufacturing

sub-contracting.

The management of documents, conversion are required (many s/w systems were used)

Management of user privileges can be used to give subcontractors direct access to the

principal’s information processing systems, to certain document classes or work, so that

they will have selected rights (viewing rights)

DXF, STEP, CALS, IGES, SGML and XML standards.

Sourcing and procurement

The life cycles of products and components are shortened.

80% of the cost of the product is determined during the product development phase

PLM Business Objectives

PLM Limitations

UNIT- III DETAILS OF MODULES IN A PDM/PLM SOFTWARE

MET

BICYCLE HELMET INNOVATOR REDUCES PRODUCT DEVELOPMENT CYCLE

BY SIX MONTHS WITH NX

By integrating computer-aided design with structural analysis, MET significantly

improves collaboration with subcontractors, streamlining production of tooling and molds

MET S.p.A is a global leader in the production of helmets for professional cyclists.

The MET name has become a synonym for accuracy, reliability, efficiency and

sustainable development.

CHALLENGES

Develop products that combine elegance and safety

Optimize helmet construction in the early stages of the development cycle

Manage intricate surfaces with many complex nodes

KEYS TO SUCCESS

NX for the 3D modeling of concept sketches drawn by designers on paper and for

complex surface modeling

RESULTS

Reduction of product development cycle from 12-14 months to 6-8 months

Rapid prototyping of full-scale models with centesimal accuracy, built directly from 3D

CAD model geometry

Ability to check production tooling feasibility in the virtual domain and perform virtual

tests for certification purposes

One of our greatest concerns is surface complexity; each model has a huge number of

surfaces, with plenty of changing curves, intersections and fillets.

A big plus of using NX is its capacity to handle our sophisticated surfacing needs.

NISSAN MOTOR

Continuous improvement – design through delivery

Automotive industry is now engaged in “one of the greatest engineering competitions in

history.

To ensure that Nissan is one of the winners, the company is now building on the success

of a program Ghosn initiated in 2001. Called V-3P (Value Up for Product, Process and

Program Innovation),

Quality has improved significantly as well under the V-3P program.

This was determined in two ways

One was a reduction in design changes, which ranged from a 60-percent to a 90-

percent decline.

The lower figure was achieved on a vehicle program that included a significant amount of

new technology.

The 90-percent reduction was found on a follow-up vehicle program based on an existing

platform.

The other way that quality was measured was in the number of problems reported after a

vehicle was released to the market.

By this measure, the V-3P program excelled, reducing this number by 80 percent.

Business initiatives

New product development

Commonization and re-use

Enterprise data management

Business Challenges

Ongoing time-to-market pressures

Consumer mandate for more environmentally friendly cars

Global customer base and supplier network

Keys to Success

Re-use of validated design data and concepts

Virtual validation replaces all but one physical prototype

Production requirements addressed earlier in the design process

Single source of vehicle data

Results

Development cycle reduced from 20 months to 10.5 months

80 percent fewer problems after vehicle release

Design changes reduced by 60 percent to 90 percent

Better-than-expected ROI

Valeo

Valeo is structured around four business units

o Comfort & Driving Assistance Systems

o Powertrain Systems

o Thermal Systems

o Visibility Systems

Business Challenges

Reduce CO2 emissions in all market segments

Develop technologies that enable smarter and safer driving

Keys to Success

Use Simcenter Amesim to perform rapid evaluation of new technologies

Reduce CO2 emissions primarily by modifying the powertrain system

Create, test and validate new concepts within a restricted time and cost framework

Enhance presence in Asian emerging markets

Results

Facilitated rapid decision making when evaluating new projects

Reduced the required number of physical test sessions

Optimized costs by standardizing the use of mechatronic system simulation

Played a central role for the Powertrain Innovation Department in the entire development

process

Simcenter Amesim

In order to optimize costs, Valeo, through its innovation departments, tries to standardize

the use of mechatronic system simulation to assess the efficiency of systems and concepts

to validate them in the end.

Simcenter Amesim enables Valeo to better understand the behavior of systems and

subsystems, accelerating innovation while reducing costs

How Siemens PLM Software solution does helps Dongfeng Commercial Vehicle in

investigating the Rankine cycle concept to boost truck fuel efficiency?

Physical layout of the Rankine cycle

1. Pump, 2. Boiler, 3. Turbine, 4. Condenser

The Rankine cycle is an idealized thermodynamic cycle of a heat engine that converts

heat into mechanical work while undergoing phase change.

o Process 1-2 is [Isentropic compression]

o Process 2-3 is [Constant pressure heat addition in boiler]

o Process 3-4 is [Isentropic expansion]

o Process 4-1 is [Constant pressure heat rejection in condenser]

DONGFENG MOTOR CORPORATION

Founded – 1969 (51 Years ago)

Leading truck manufacturer optimizes engine cooling controls strategies with Simcenter

Amesim

As a leading transport service partner in China, DFCV is currently working on engine

fuel efficiency to optimize freight transportation patterns.

Siemens Digital Industries Software solution helps Dongfeng Commercial Vehicle

investigate the Rankine cycle concept to boost truck fuel efficiency

Business challenges

Cut truck development costs and time

Reduce the number of prototypes and the use of test benches

Maintain a competitive edge by implementing energy recovery concepts

Why to boost truck fuel efficiency?

In 2010 heavy-duty trucks represented only 4% of registered vehicles in the United

States,

but accounted for approximately 25 percent of on-road energy use and greenhouse gas

emissions.

Currently (2017) nearly 60 percent of the energy contained in the fuel of a heavy-duty

truck is wasted in the engine through

o pumping,

o friction,

o cooling and exhaust losses.

The payback period for energy-efficient technologies is sometimes less than one year,

which is 5 to 10 times faster than for cars.

Thus, heavy-duty truck manufacturers, are accelerating their efforts to develop efficient

energy recovery concepts.

Using Simcenter Amesim helps DFCV validate advanced controls strategies of the modern

diesel engine’s cooling system.

One of the most promising approaches for the truck industry is the exhaust heat recovery

technology with a Rankine cycle system.

In a closed Rankine cycle loop, the working fluid, heated by exhaust gases, turns into

vapor.

Then the fluid vapor runs a turbine, which can be directly linked

o either to the crankshaft of the engine

o or to an electric generator.

In spite of controls and design complexity, there is rising interest in this technology

because it would allow truck producers to improve overall fuel efficiency by

approximately 5 percent.

Conquering the largest market

Due to its rapid economic growth, China - the world’s largest heavy-duty truck market,

representing more than 40 % of the global share.

To gain access to the promising Chinese market and share development costs of new-

generation engines, European and American truck manufacturers are establishing joint

ventures with local truck producers.

At the same time, this cooperation allows Asian truck original equipment manufacturers

(OEMs) to reinforce their technical expertise and worldwide presence.

In January 2013,

o Dongfeng and Volvo (the Swedish auto manufacturer) agreed to form a China-

based medium

o heavy-duty truck manufacturing joint venture,

o Dongfeng Commercial Vehicles, with 45% ownership by Volvo.

As part of the transaction, Volvo will pay 5.6 billion yuan to Dongfeng

Overcoming Business Challenge (No 2)

With Simcenter Amesim, we have reduced our development costs significantly because

we no longer need to use a test bench to validate our controls strategies

Enhancing diesel engine control strategies

What is the best way to optimize fan controls to save fuel while maintaining cooling

performance?

How could a controlled thermostat or water pump improve the cooling system

performance?

We (DFCV) needed a simulation tool that would allow us to understand all of the

technical issues of a complex system such as an engine,

by modeling its combustion,

cooling,

lubrication subsystems

and then integrating these subsystem models into the entire vehicle model

The lubrication circuit is one of the engine subsystems that DF CV models with Simcenter

Amesim in order to integrate it into the entire vehicle model.

DFCV models the Rankine cycle loop using the two-phase flow library of Simcenter Amesim.

Engine Development Department

The Engine Development Department turned to Siemens Digital Industries Software for

help, following a benchmark

Using Simcenter Amesim, we now assemble all engine subsystems in one model in order

to test controls strategies to assess fuel consumption via co-simulation between an

Simcenter Amesim and Simulink models.

We can not only analyze the fuel efficiency of our existing architectures, but also

capitalize and re-use the same model to optimize current designs.

Taking the lead with energy recovery concepts

Our research and development activity around the Rankine cycle technology wouldn’t be

possible

o without the two-phase flow library of Simcenter Amesim

o as well as other predefined and validated multi-domain Simcenter Amesim

components,

which allow us to analyze the effect of this innovative approach under real driving

conditions before the first prototype has been produced.

Performing co-simulation with models utilizing Simcenter Amesim and the Simulink®

environment allows DFCV to save testing time.

Keys to success

Design an efficient engine cooling system with advanced controls strategies

Optimize existing diesel engines by considering different design options

Analyze the impact of the exhaust heat recovery technology under real driving conditions

Results

Optimized engine cooling controls strategies

Analyzed behavior of the combustion, cooling and lubrication subsystems in the context

of the entire vehicle

Studied Rankine cycle technology before the first prototype was available

PLM CASE STUDIES IN JAPAN

BUSINESS STRATEGIES AND KEY INITIATIVES

This case study introduces PLM business scenarios of three Japanese manufacturing

firms.

o Case 1—“Implement PLM Prior to ERP”

o Case 2—“PLM as Working Space for Designers”

o Case 3—“Don’t Customize, but Use PLM as It Is”

They come from three different kinds of business situations.

PLM History in Japan

In Japan, PLM as a technical term was first seen in about 1995.

At the time, concurrent engineering using 3D CAD data was booming, but the product

design engineering style of Japanese firms was more focused on 2D drawings than on a

3D model data centric approach.

Therefore, PLM was often positioned as a drawing data management system

Bills of Materials (BOM) managed by ERP/MRP systems rather than PLM systems.

2007 Problem

Millions of veteran engineers would retire by the year 2007.

So PLM as not only a simple product information management system, but also as a

knowledge management system

2011 Earthquake

Business strategies of Japanese firms became focused on the life-and-death problem of

continuing operations rather than innovation in product development.

Strengthening SCM and ERP systems had higher priority than PLM and CAD initiatives

Interest in PLM declined.

2020 Tokyo Olympics

Has encouraged many Japanese companies to express their concerns about their current

PLM systems not being able to cope with operational changes.

As of December 2018, there is an increasing need in Japan to replace or rebuild aging

PLM systems.

Japan is facing a rapidly aging society; one in four people is now over the age of 65.

The Japanese government is encouraging digital transformation, with drastic reforms to

the working practices of white-collar workers.

Presently, an increasing number of companies are working with product development

systems that make development highly productive, even with fewer people.

Japanese manufactures are increasingly pursuing PLM systems combined with internet of

things (IoT) technologies.

CASE 1—“IMPLEMENT PLM PRIOR TO ERP”

Company “A” is an industrial machinery manufacturer.

Recently, the company decided to renovate its aging PLM system.

INTENTION – to support the design of similar products that account for more sales

efficiency.

AIM - speedy response to new product development.

Issues Faced

Major issues with creating a bill of materials (BOM) in the drawing work of the design

phase.

This work was time consuming

There was no data connectivity among BOM, 2D drawings, 3D models, and technical

documents, as each of these was managed in disparate IT systems.

ad hoc basis

No integrated work management

Balancing of design work burden

Awareness

Head of the factory Mr.X (who had spent most of his career on the shop floor earlier

days) was aware of this problem.

He believed that implementing an ERP would lead to improvements but data connections

between design and manufacturing were extremely poor.

Break in workflow when a designer was on long leave.

Presently, Company A is riding a booming economy and aims to use this opportunity to

expand its business as much as possible.

Sharing linked information between design and manufacturing would be too time-

consuming.

He began to wonder if the cause of this issue was a lack of functionality in the company’s

existing PLM system

He still believed that the ERP system was the most important IT system, but ERP alone

was not good enough

He accelerated the decision to renew the PLM system before addressing ERP.

Why was it necessary to implement PLM before ERP?

Various issues and troubles were beleaguering (Annoy persistently) the factory.

Product design related mistakes were commonplace.

For example, despite a design change, the drawings held by the manufacturing

department were often obsolete

In addition, it was discovered that some components used by the company were no longer

being manufactured.

The designers tended to keep their own product drawings of the products for which they

were responsible, but it was difficult for others to locate those drawings

“The situation is no good. If we don’t integrate and manage design data properly in

a PLM system, we will not be able to do design work. Our current management

methods are at a breaking point”

His conclusion was that “ERP alone will not work. The upstream design processes are not

sending down proper data. This means that we need PLM before ERP!”

Results

First, data searches became faster

All design data were integrated within a single PLM system, allowing all necessary data

to be found in one search

PLM’s access control function played a role in reducing the risk of mistakenly losing

other people’s data.

In the future, it is expected that expanding the rollout of new PLM functions will

rationalize design work for similar designs, making sure sufficient labor is available for

designing new products.

Concerning design drawings, the PLM system promotes the distribution of 3D model

data.

reduce manufacturing rework requirements and associated costs.

CASE 2—“PLM AS WORKING SPACE FOR DESIGNERS”

Company B designs, manufactures and sells highly creative products for various types

of urban office buildings and public facilities.

In the last decade

o faced severe competition regarding product development

o challenging to generate products with fresh designs and functionality

Situation in the year 2000

The product designers

o were geographically dispersed,

o and none have experienced the digital engineering, using 3D CAD and PLM

Working at a manufacturing site had a positive result in product designs that showed an

understanding of manufacturing requirements.

However, these people were located far from the metropolitan areas that contained the

company’s target markets and customers.

Mr. X and his Idea

Mr. X (head of product development) worked for a long time in the sales division.

Though he had no knowledge of product technology,

o he was appointed so that products developed would be competitive from a sales

perspective.

First decision

o product designers work near big city markets, because he felt they should work

close to the sales department.

o Therefore, Mr. X decided to move the designers to Tokyo.

What is an ideal work environment for product designers?

Mr. X began to feel the need for the kind of infrastructure favored by designers who seek

to be creative.

o Infrastructure - IT foundation

For designers, the space must be comfortable or else good ideas are simply not created.

Earlier when they worked in the factory, they create product prototypes with complete

freedom to move around.

However, the Tokyo office space was congested.

The product development done in that cramped and stressful place led to delays,

generated higher costs, and worsened teamwork with the factory.

These problems were later solved almost instantaneously by moving to a more spacious

design-studio office.

This meant that providing an open physical space was extremely important for the

company’s designers.

In order to produce hit products, is it good enough to only provide the right physical space?

The members of the design team spent more time creating documents on word processors

than they did with the CAD systems.

With his sales background, Mr. X was doubtful that his designers were really able to

focus on their design work.

In addition, the version of CAD software was out of date, and nothing was being done for

product data management.

Mr. X noticed that, “Designers need more than just a physical space. The work of design

revolves around digital data, and a digital space is needed to manage that digital data!”

This was a recognition that the design division needed the IT infrastructure of product

information management.

PLM and its value

Mr. X began to study PLM seriously and came to understand its value.

Management team agreed on PLM’s value by calculating it based on the management

metrics

The company defined a key performance indicator—“Net Creative Time”.

Mr. X came to believe that there was a need not only for a

o “physical space” but also a

o “digital space” in the form of PLM to really bring the talents of designers to full

bloom.

Results

In practice, the first step in implementation of PLM were CAD data management and

linking BOM with the ERP system.

In other words, by rationalizing unnecessary work in detailed design, the company could

focus on creating “Net Creative Time” for designers.

In addition, assigning lots of people to create two dimensional drawings by hand was

extremely inefficient.

One of the benefits of PLM is automatic generation of product variants.

Future Scope

A plan to create a decision system to give further feedback to the management team.

CASE 3—“DON’T CUSTOMIZE, BUT USE PLM AS IT IS”

Company C - manufacturer of metrology equipment and related solutions.

Mr. M (executive for company-wide IT)

Mr. M always instructed his managers, “Use the standard functionality of packages as

much as possible.”

Why Customization?

He emphasized that work tasks that do not contribute differentiation of the company,

from others should be adapted to off-the-shelf IT packages to ensure that the package

functions efficiently.

Of course, whatever work that does enable company differentiation may indeed

require customization,

o but Mr. M recommends first using standard functionality provided by IT vendors

for ERP and PLM systems in particular.

Is customization leads to problems

In the past, Mr. M had accepted many proposals by external system integrators to

customize systems when implementing systems.

However, he was not able to back away from those customizations, which ended up being

expensive in terms of system development and maintenance.

If there is sufficient IT budget for investment, companies are better off rather

o investing in things that add value,

such as technology development for product innovations, or production

process innovations

o and not customization of software.

Mr. M was successful without customizing the ERP system, using standard functionality

as much as possible.

o standard functionality would be used when implementing the PLM system.

PLM is used in development and design to generate product innovation and it was said to

be difficult to standardize.

PLM implementation is targeting lean engineering.

Results

Company C’s PLM projects went live after an implementation period of 12 months.

Afterward, the use of standard functionality in the company’s PLM was still kept at 99%.

This PLM system is clearly positioned as one piece of a company-wide IT strategy.

Company C aims to create a single “trinity” system comprising PLM, ERP, and MES.

This will be critical in helping them achieve their aim of becoming a leading smart-

factory company in their industry.

UNIT-IV ROLE OF PLM IN INDUSTRIES

PLM Vision

A PLM Vision represents the best possible forecast of the desired future PLM situation and

activities. It outlines the framework and major characteristics of the future activities. For some

companies, one step in the Initiative will be to develop and communicate a PLM Vision for the

future environment.

A PLM Vision communicates the fundamental “what’s, why’s and where’s” of PLM for the

company. It provides a Big Picture to guide people in the choices they have to make, when

strategising and planning, about resources, priorities, capabilities, budgets, and the scope of

activities. There’s a saying, “a ship without a destination doesn’t make good speed”. Without a

PLM Vision, people won’t know what they should be working towards, so won’t work

effectively.

Development and maintenance of the PLM Vision is a 17-step activity

1. Start the Visioning activity

2. Clarify the objectives

3. Identify the factors to be addressed

4. Identify the questions to be answered

5. Get information to answer the questions

6. Develop some drafts of the Vision (scenarios)

7. Document the scenarios

8. Test the scenarios to see if they answer the questions and meet the objectives

9. Unless there are at least three reasonable scenarios, return to Step 3

10. Carry out SWOT analysis on the reasonable scenarios

11. Identify the preferred scenario

12. Add the strengths of the other scenarios to the preferred scenario

13. Test the scenario to see if it answers all the questions and meets the objectives

14. If there are doubts about the scenario, return to Step 3

15. Document the Vision that answers all the questions and meets the objectives

16. Write the PLM Vision Report

17. Maintain the Vision

Title : The PLM Vision Report

Table of Contents

Executive Overview

Section 1 The PLM Initiative

1.1 Recommendations from the PLM feasibility study

1.2 Driving forces for PLM

1.3 Critical issues for PLM

Section 2 - The Company

2.1 Company objectives and strategy

2.2 Key success factors for the company

2.3 Key issues : markets, customers and competitors

2.4 Key issues : products

Section 3 - The PLM Vision Development Approach

3.1 Data gathering

3.2 Scenario development

3.3 SWOT analysis

3.4 Scenario selection

Section 4 - The PLM Vision

Appendices

1. Team Members

2. Interviews

3. Details for each specific area

PLM Strategy

The future PLM Strategy describes how PLM resources will be organised, managed and used to

achieve the objectives

Developing the future PLM Strategy is a 9-step activity

1. Start the activity to develop the PLM Strategy

2. Clarify the reporting requirements

3. Create the report structure

4. Gather information about the Future Situation

5. Develop Candidate Strategies (scenarios)

6. Select the Preferred Strategy

7. Finalise the PLM Strategy Report

8. Present the report

9. Communicate the Strategy

Title : The PLM Strategy Report

Table of Contents

Executive overview

Section 1- The company

Company objectives and strategy

Critical issues and key success factors for the company

Strengths and weaknesses of the company’s competitors

Section 2 The surroundings

Recent changes in the environment

Current environment

Expected changes in the future environment

Section 3 - The activities in the lifecycle

PLM objectives

Current situation of PLM activities and resources

Future situation of PLM activities and resources

Brief description of the selected PLM strategy

Analysis of the selected PLM strategy

o strengths and weaknesses

o response to opportunities and threats

o fit to company strategy

Section 4 - Detailed description of the PLM strategy. Organisation and policies;

products and services; portfolio; customers; activities, processes;

facilities; human resources; technology; practices; information;

information systems; standards; relationships with other activities;

interfaces; operations; metrics; planning and control; quality; finance

Section 5 - Change strategy

Section 6 - Outline strategy implementation plan

major projects: objectives timing, resources, costs, benefits;

project dependencies, priorities, organisation

Section 7 - Outline first year operating plan

Appendix 1 Detailed information about the Future Situation

Appendix 2 Detailed information about Strategy development and selection

PLM Implementation Strategy

The PLM Implementation Strategy shows how resources and activities will be organised to

achieve the future PLM Strategy. It shows the activities that have to be carried out to get from

the current use of PLM resources to the future use of PLM resources.

10 steps to develop the PLM implementation strategy

1. Start the activity to develop the PLM Implementation Strategy

2. Clarify the reporting requirements

3. Create the report structure

4. Gather information about the Current Situation and the Future Situation

5. Understand the factors that may influence timing and priorities

6. Develop Candidate PLM Implementation Strategies (scenarios)

7. Select the Preferred PLM Implementation Strategy

8. Write the PLM Implementation Strategy Report

9. Finalise the PLM Implementation Strategy Report

10. Present the report

PLM Implementation Plan

Once the PLM Implementation Strategy is known, an Implementation Plan, built up of

manageable and prioritised sub-projects, should be developed. This should show how the overall

vision will be achieved over the Initiative timeline. It should address the long term and the short

term.

For the long term, the plan provides executives with the information necessary to understand

activities, resources and timelines. The more specific the plan, the better. It should define an

overall implementation timetable. It should show how the PLM implementation will be split into

manageable phases

UNIT-V BASICS ON CUSTOMISATION/INTEGRATION OF PDM/PLM SOFTWARE

Integration of the PLM system with other applications

Different ways to integrate PLM systems

In a PLM project, it is necessary to decide what kind of information will be updated in

each system.

The central question to be examined is the ownership of the information in various life-

cycle phases.

A reasonable objective is that information should always be updated in one place.

Other systems can read information directly from the PLM databases, and if necessary,

the required information can be replicated on the databases of other systems.

System integration and related problems are often the most difficult and most laborious parts of a

project.

It is not necessary to integrate the PLM system with all other systems in the company.

1. Enterprise resource planning (ERP) systems

2. Document management systems

3. Mechanical or electronic CAD systems

4. Other design applications, image editors

5. Applications for cost accounting and bookkeeping

6. Customer relationship management (CRM) or other sales applications

7. Reporting systems

8. e-Mail programs

9. Office applications

10. Viewers

11. Internet browsers

The level of integration can vary considerably.

Information can be moved between PLM and other applications in several different ways,

o from the manual transfer and copying of files to sophisticated database or

middleware integration between systems.

APPLICATION - TWO OPPORTUNITIES

An application has two opportunities to acquire the information it needs:

o information transfer

o information sharing

Information transfer involves copying the information prior to moving it.

Shared information involves the use of one common database.

Many different applications have access to a single database, if necessary at the same

time.

Three commonest ways to integrate systems

1. Transfer file integration

2. Database integration

3. Middleware integration

It is often easier to transfer information than to share it,

because sharing information requires an exact knowledge of the basic mechanisms of the

software in use and sometimes involves application specific tailoring.

However, the problem with information transfer is that it is often extremely difficult to

ensure the harmony of information after copying and transferring files.

Later changes in moved information are not necessarily updated in the original database.

One could say that the transfer of information is suitable for communication between

separate companies and organizations.

The sharing of information is a good solution inside a company, where applications can

be more tightly integrated.

Transfer file

Information is usually moved as a so-called transfer file, which is created either manually

or automatically in the application from which the information is exported.

The generated transfer file is read, manually or automatically, by the application into

which the information is imported.

As always in integrating applications, common terms and concepts must be clarified

carefully

There must be exact agreements on:

o What information is moved?

o How is the information moved?

o In which file format is the information moved?

The transfer file can be,

o for example, a *.txt or *.csv-type text file in which the fields to be moved are

distinguished from each other using a separator character, such as “;” or “|”.

The example might create the following line in a transfer file:

465259; ; PLATE; S=20; pieces; P004310; A;

465259; ; PLATE; S=20; pieces; P004310; A;

Database integration

This is still a case of transferring information, but the method used is database integration

instead of a transfer file.

Database integration is often carried out through a so-called API (Application

Programming Interface).

A PLM application could offer, for example, the following API functions as services to

other applications:

- Retrieval of information, for example searching for documents or items with a

certain code

- Free text-form search of information using AND/OR/NOT functions

- Retrieving the structure of a certain item

- Adding information to the database

- Editing information in the database

Advantages of transfer file integration

■ Easy to implement

■ Inexpensive solution

■ Easy to make changes

Disadvantages of transfer file integration

Slow, does not operate in real time

Information has to be replicated over several databases

Timing/launching of the transfer file often involves manual work

Management of several transfer files can be difficult

Advantages of database integration

■ Speed

■ Ability to use common databases for several applications

■ Information in one place

■ Automatic

Disadvantages of database integration

■ Implementation can be quite heavy

■ Making changes is more difficult

■ Expensive

EAI - Middleware integration

Many companies began to develop large-scale integration for transferring information

between systems.

However, this development led to a huge amount of work due to the large number of

specialized systems and to the ineffectiveness of tailored integrations.

Integrations have to be built individually in the form of tailored links from system to

system.

Maintenance of these integrations is quite laborious

Enterprise Application Integration - process like data transfer and distribution possible

between different applications in a company’s data network.

Helps in moving information more effectively within and between companies.

It integrates different systems with each other with the help of a common generally

functioning layer.

Instead of separately integrating specific systems,

o the EAI adds to the IT architecture of companies a software layer (middleware)

that transmits and moves the required information between different systems

Advantages

o The need for integration between the systems decreases

o Reduce the amount of work needed for the maintenance of the integration

EAI is multiform and still a little open.

The exact nature of the concept can therefore vary in different connections

Many people said definitions for EAI, but is simple it is

o Middleware (EAI) software can be used to reduce the number of integrations and

make them easier to manage

SYSTEM ROLES